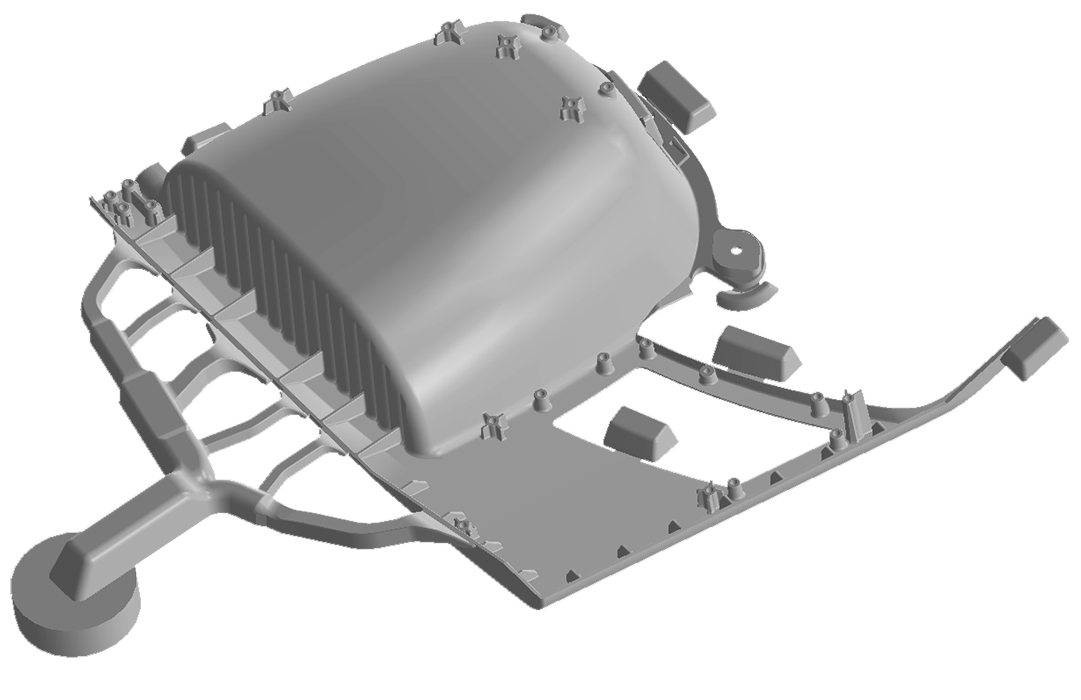

What We Do

HPDC gating design services provided by EKK Inc. will save your company time and money all while resulting in a better final casting. We will work closely with you to design a complete gating and overflow system for your casting. Our tried-and-true approach towards gating design overcomes the limitations of traditional gating design techniques to help you be as competitive as possible in today’s global market.

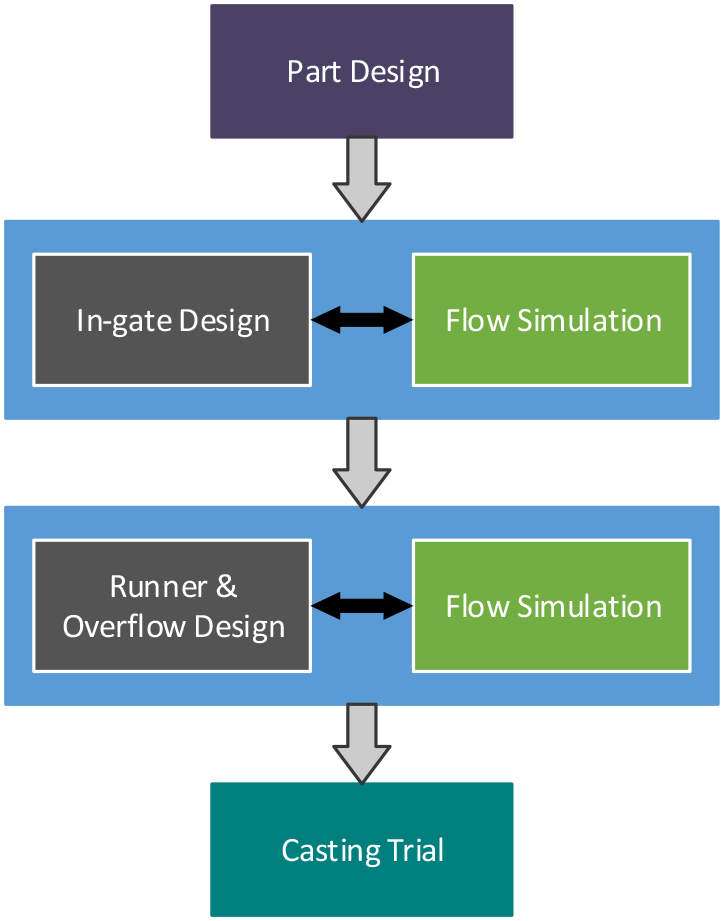

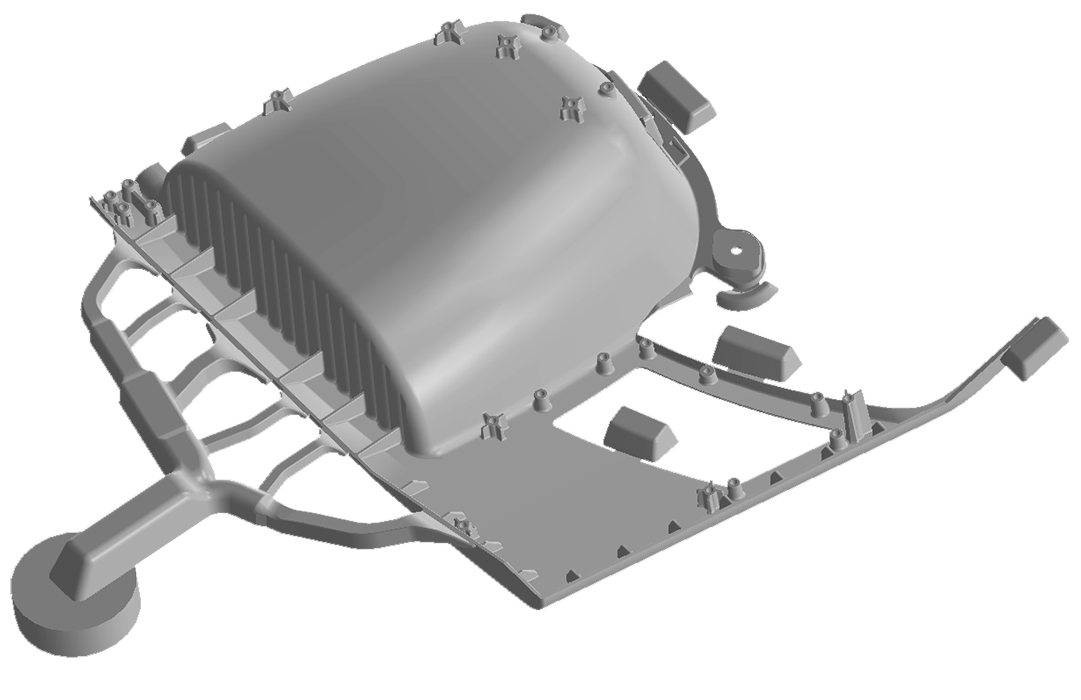

Iterative Design Process

To assure the optimal flow pattern and casting properties are obtained within the final part, we iterate and simulate designs while we progress through the design process.

Simulation Verification

The EKKcapcast software suite is used throughout the design process to ensure the best possible design decisions are being made.

Complete Design

The final runner, gating, and overflow design is provided with a comprehensive report so you can rest assured your tool will only be cut once.

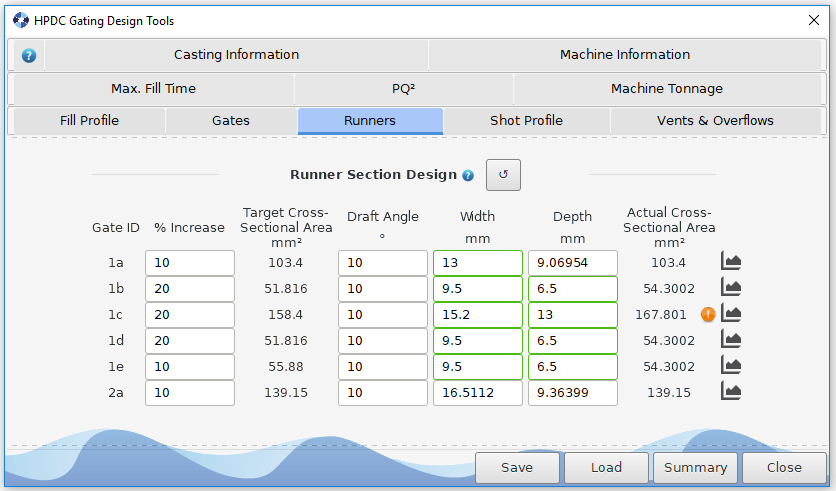

Gating Design Tools

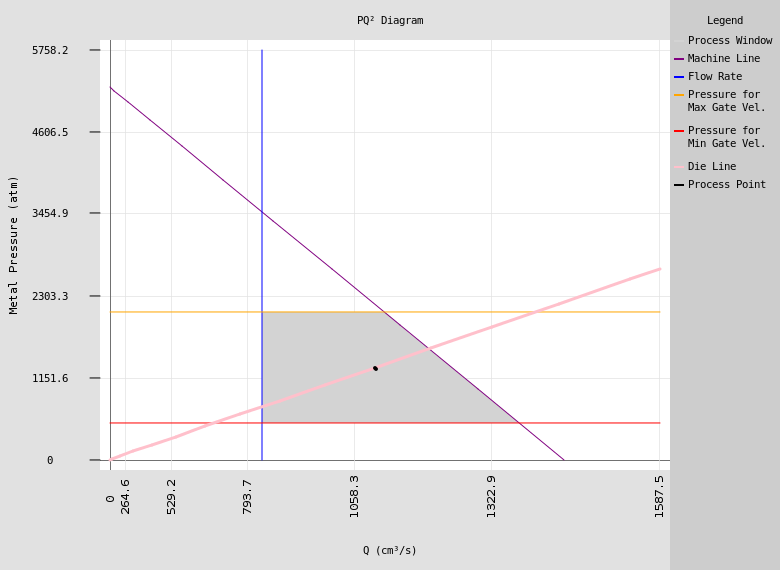

A comprehensive set of HPDC Gating Design Tools includes a variety of integrated calculators for all of your gating design needs. Castability for the casting at your plant can be determined with PQ² and Machine Tonnage tools. Calculators corresponding to each stage of EKKs Iterative Design Process provide expedient guidance, especially when designing runner and overflow systems. Throughout, various 'reality checks' help prevent mistakes.

What It Means For You

Reduce Costs

Improved yields as well as less physical mold alterations and tests results in decreased development time and part costs.

Spend Less Time

Decrease development lead times by quickly iterating your design in the virtual world. Find the best casting before you cut the mold.

Improve Yield

Optimal efficiency and design means better parts with less waste. No more over engineered gating and risers.

Know More

The amount of data collected using EKKcapcast means you'll know more about your casting process then you ever have before.

Find issues

You will be able to find casting problems and inefficiencies before you even cut the mold.

better castings

Get the best casting the first time – every time.