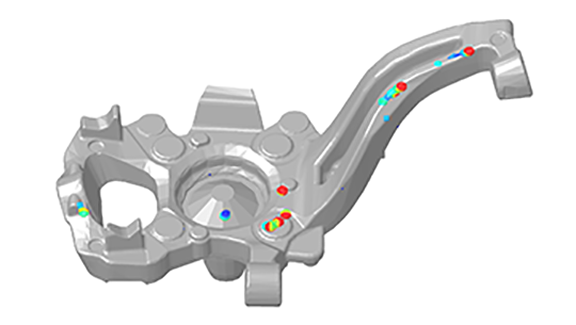

Advanced

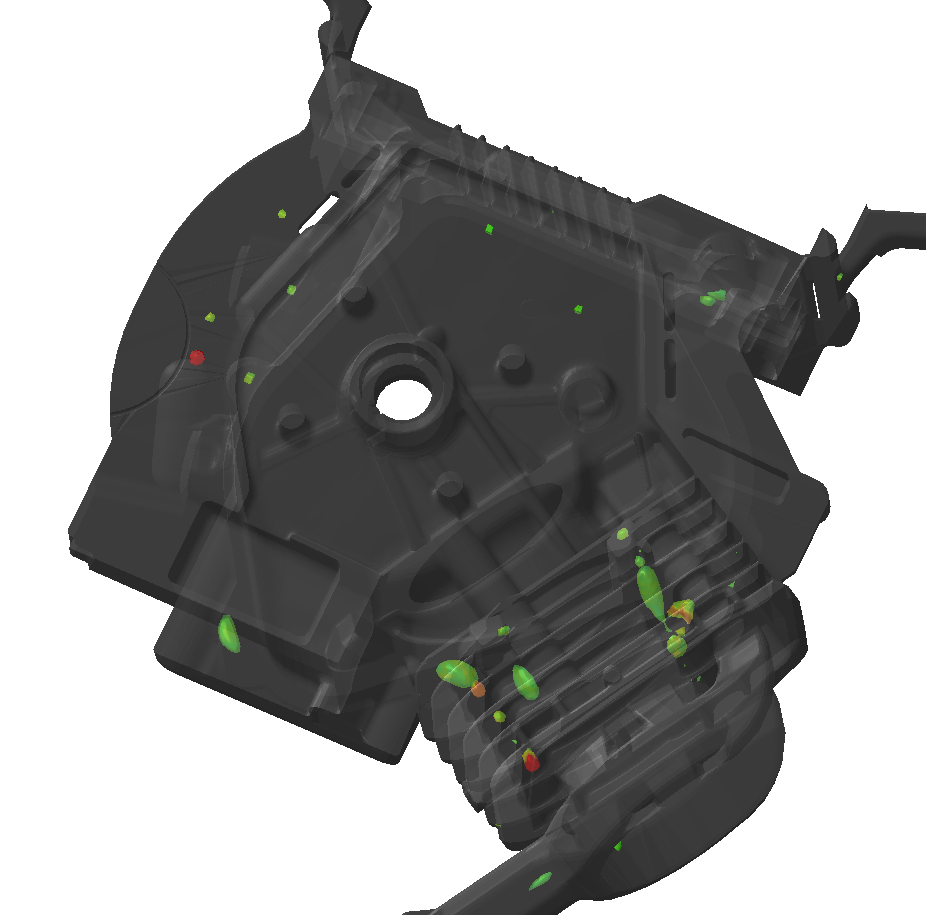

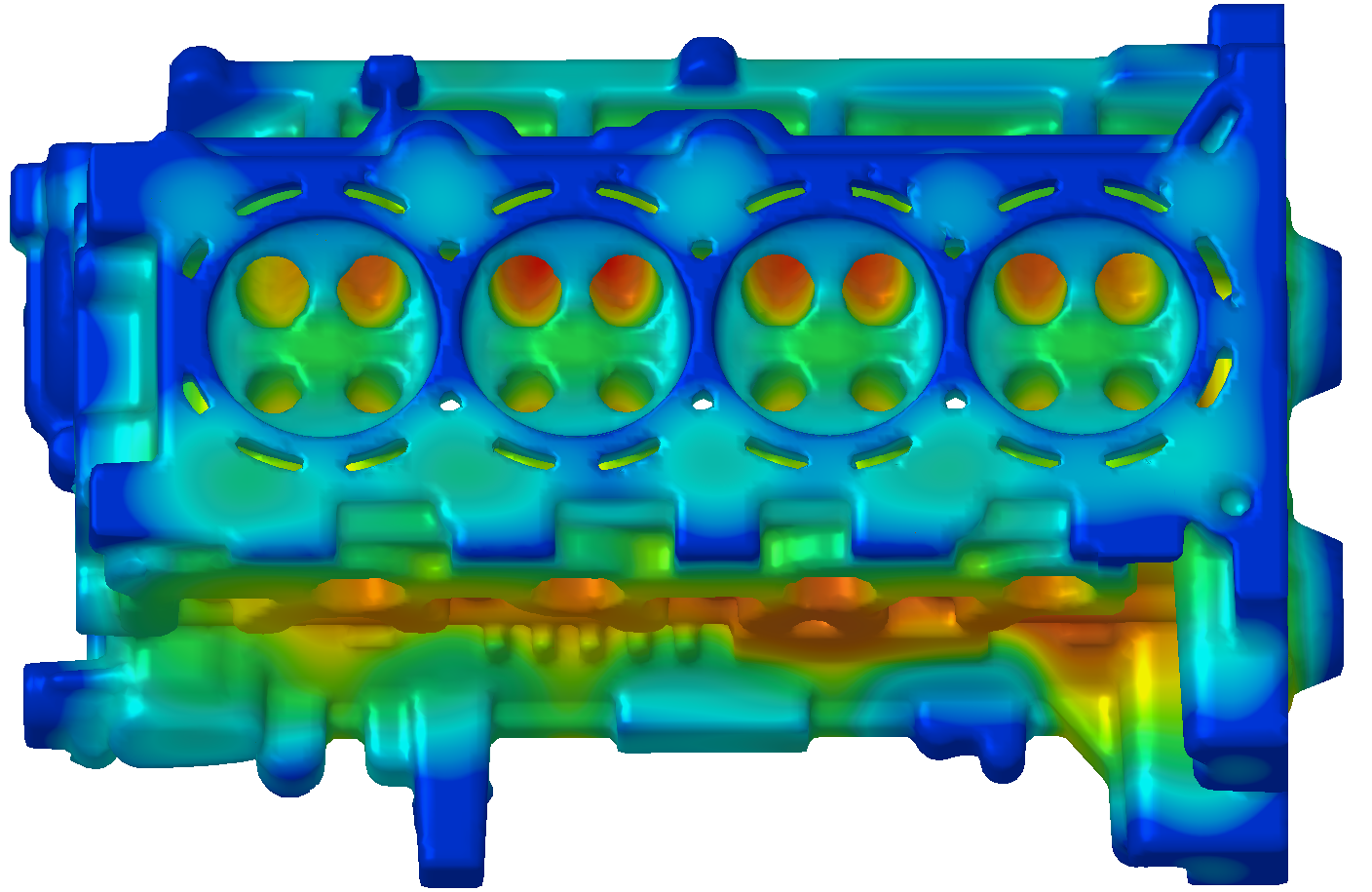

The material properties of different alloys are considered in the calculation of shrinkage porosity. Gas and metal pressure changes, cooling rates, and thermal expansion combine with hot-spot data to produce a more accurate and tailored prediction. Mechanical properties are also generated.

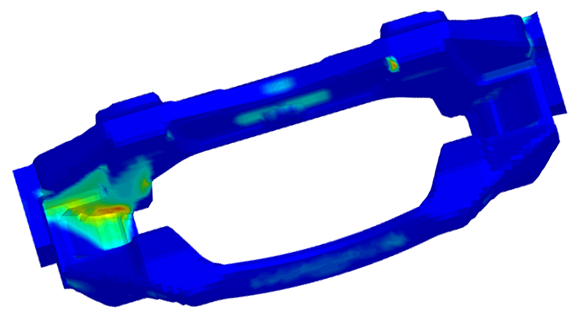

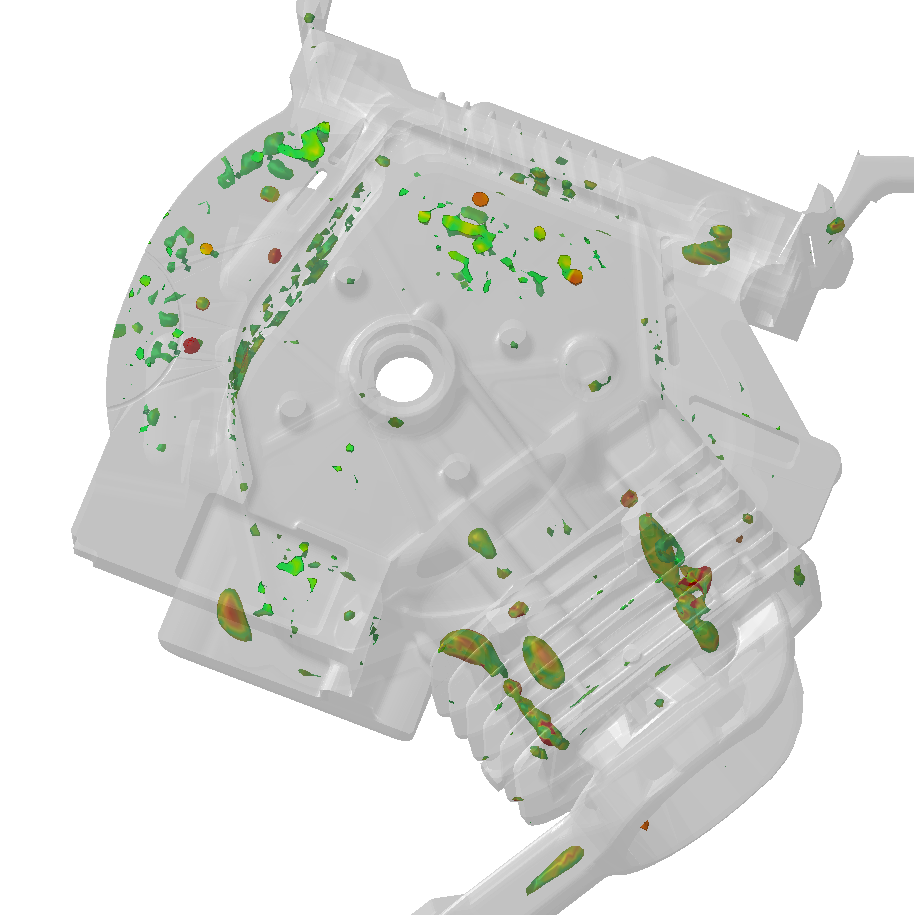

Thermal Crack

Distortion results produced by the Stress software can be combined with Porosity results to diagnose locations which are likely to experience thermal crack.

Different casting process and alloys behave differently in regard to the formation of shrinkage porosity; a specialized Porosity Module has been developed for different categories of castings.

Porosity for Al Castings

Hydrogen content plays an outsized role in the formation of porosity for aluminum castings.

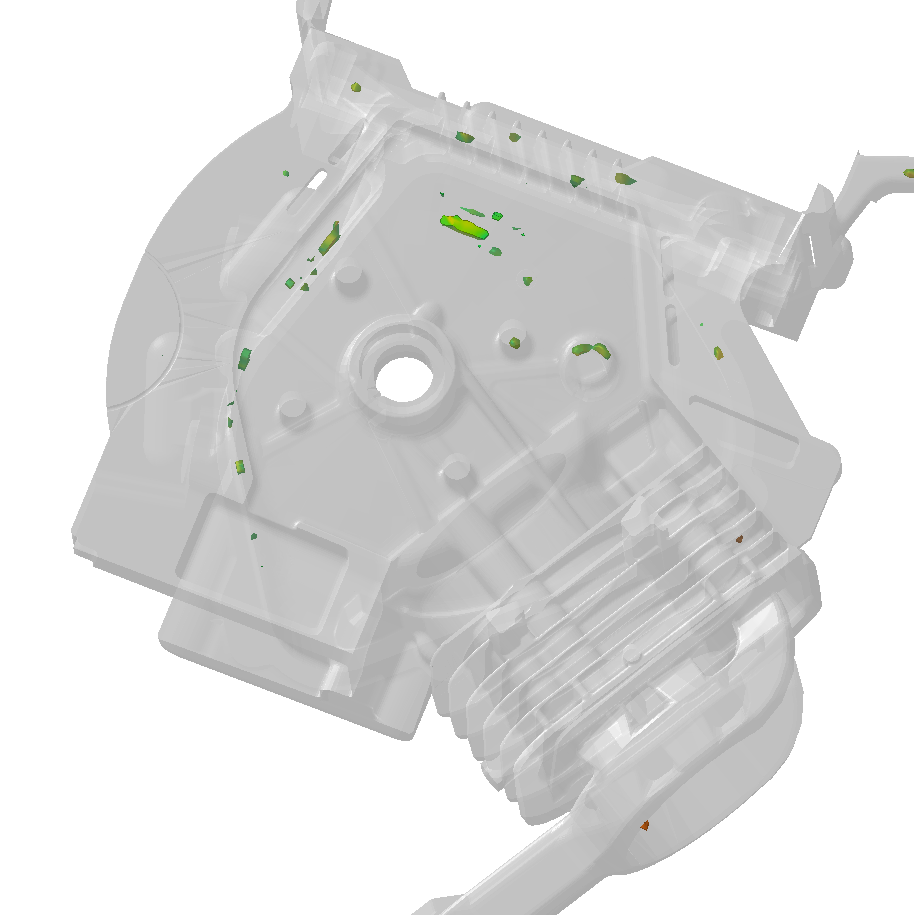

Porosity for HPDC Castings

For HPDC castings, the presence of trapped air is of particular importance in determining porosity severity. High pressures, such as from intensification and squeeze pins, are often introduced to attempt to minimize the impact of trapped air but the effects are often not easy to predict.

Higher Intensification

Lower Intensification

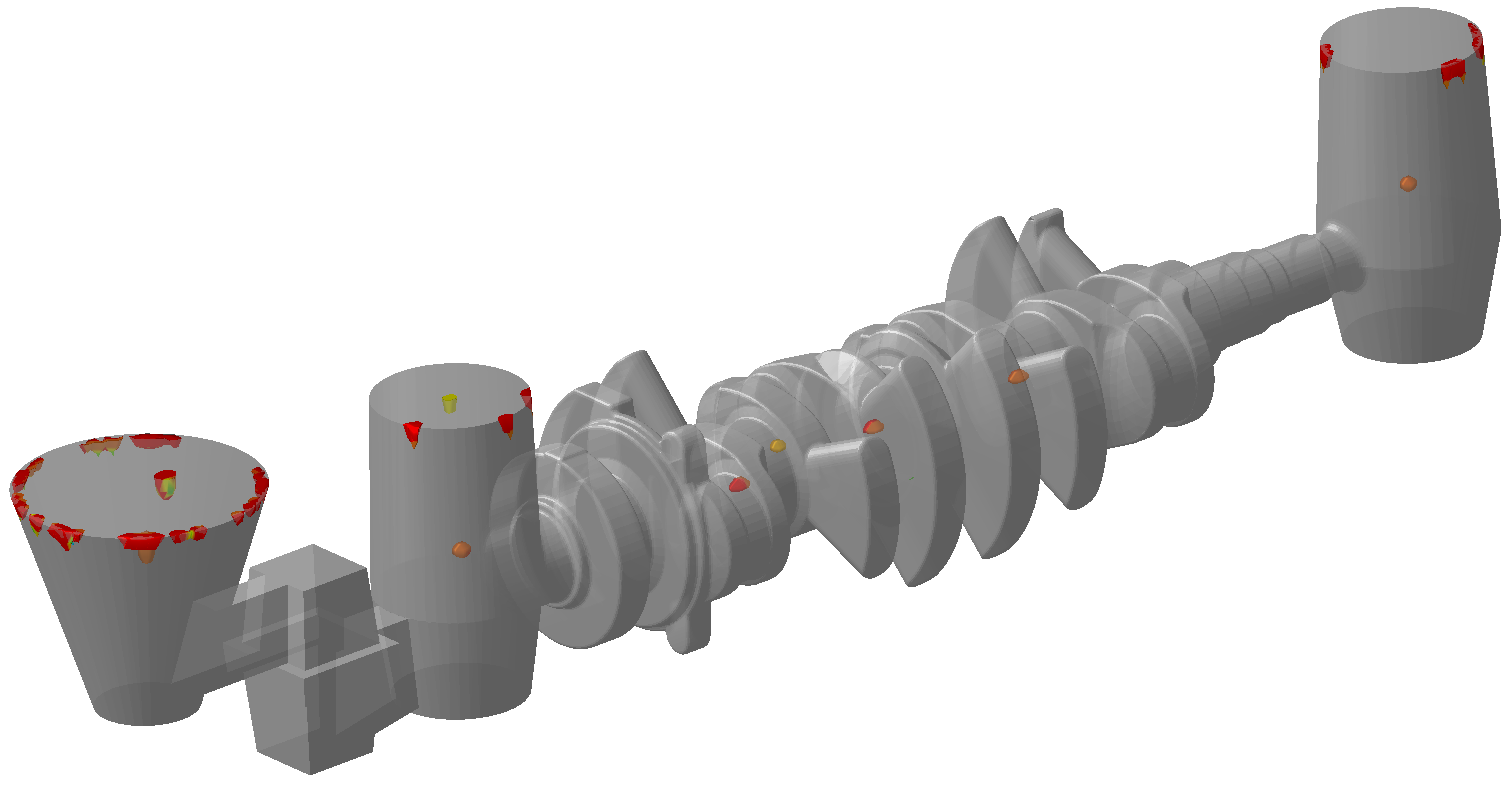

Porosity for Iron Castings

The behavior of graphite in iron castings is notable for determining the material properties of the casting. It is similarly the key to predicting porosity; traditional hot-spot data is not sufficient alone. Advanced interactions such as the expansion of graphite and inoculation are modeled. In Sand castings, the water content of green sand, and wall movements also play a role.