Powerful

EKKcapcast calculates a wide range of data to ensure you have a full understanding of what is occurring in your casting. All this data helps you get your casting right the first time.

• Venting / Trapped Air

• Vacuum

• Two-Phase Flow

• Intensification

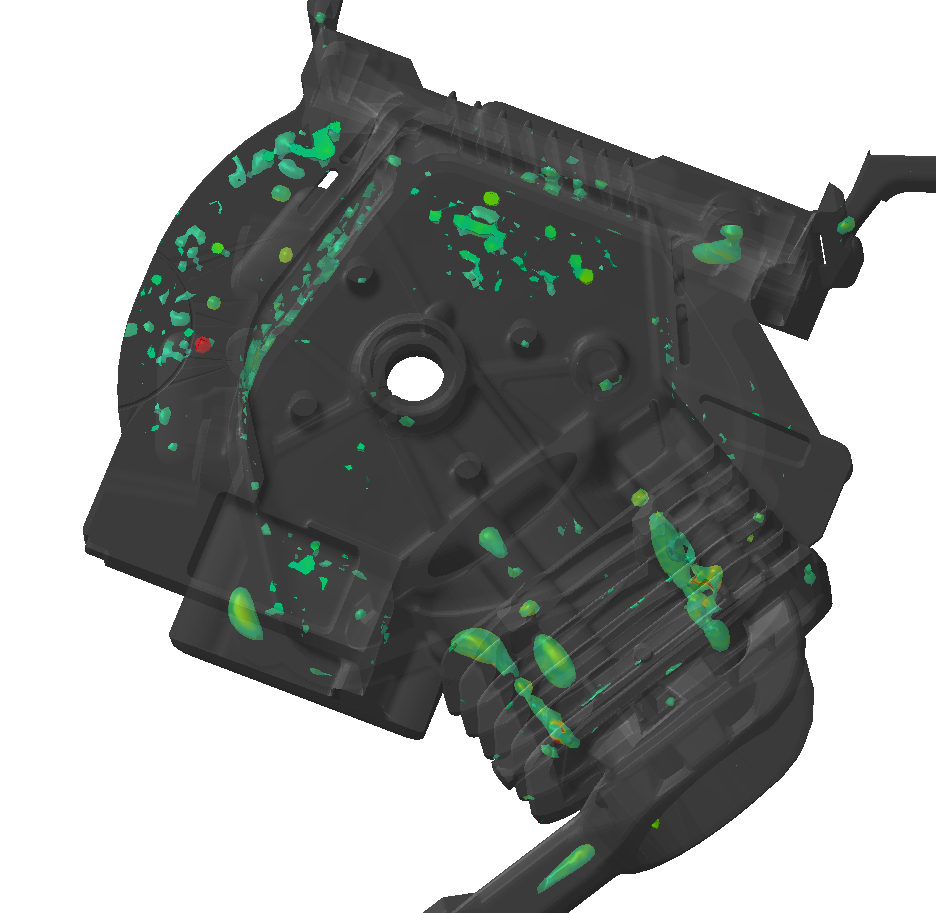

• Porosity

• Runner Efficiency

Accurate

The high quality FEM meshes produced by EKKcapcast are essential in modeling thin wall castings and geometries such as venting, overflows, and even flash. The mesh is specifically designed for use with our two-phase flow module in order to produce the most accurate results possible. Simulation results are consistently verified by real-world castings.

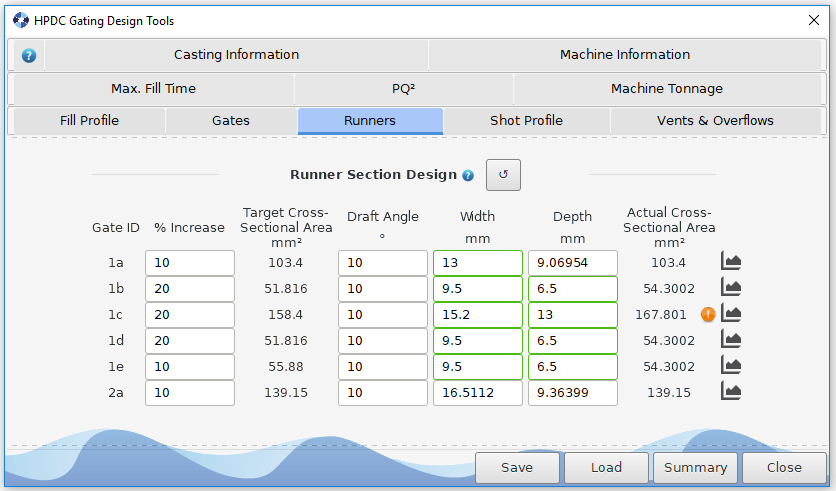

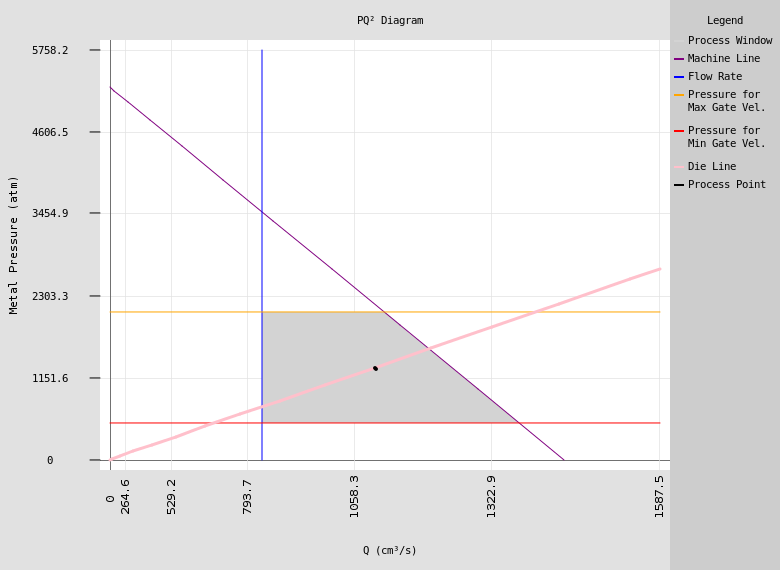

Gating Design Tools

Existing HPDC gating design tools have been consolidated into a comprehensive interface that includes functionality based on industry standards, such as fill time calculation and PQ2 Analysis, as well as powerful tools that provide guidance for developing complete runner and overflow systems for your casting. Suggested shot profiles and various 'reality checks' are also provided.

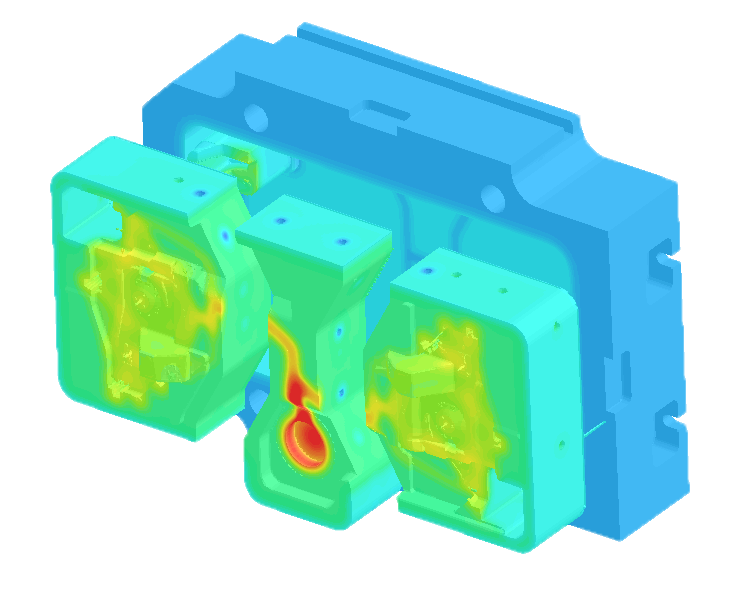

Fluid Flow

In-depth visual analysis of fluid flow patterns and various fluid properties throughout filling is possible. Determine where issues may arise due to insufficient fluid velocities, temperatures, patterns, and more. Because of EKKcapcast’s advanced two-phase flow algorithm, you can also see things like back pressure and trapped air volumes.

Shot Sleeve Simulation

EKKcapcast contains a variety of shot sleeve calculators for generating and verifying shot profiles. Simulation and visualization of shot sleeve movement quickly identifies issues. Incorporating tip movement and shot profile in flow simulations allows for the most accurate flow pattern possible.

Temperature

EKKcapcast’s thermal analysis module uses zero thickness interface elements to accurately model heat transfer between every component in the model. This gives the user the ability to analyze casting temperatures, solidification patterns, and thermal effects throughout the entire process.

Solidification

Temperature results are used to predict filling defects due to inadequate mold temperature, locations in the mold prone to soldering, as well as casting and mold thermal distortion.

HPDC Essentials

Our popular 'HPDC Essentials' package is geared towards streamlining the cost of developing a casting process while maximizing your profitability. It provides the tools necessary to eliminate most flow related defects as well as quickly verify the gating design and overflow/vent locations all at an affordable cost.

-

Mesh Generator

-

Feature Essentials Advanced Auto Mesh Generation ✓ ✓ Smart Mesh Enhancements ✗ ✓ Multi-Component Meshing ✗ ✓ Auto Addition/Removal of Cooling Lines ✗ ✓ -

Flow Analysis

-

Feature Essentials Advanced Flow Pattern - Overflow/Vent/Gate Design ✓ ✓ Gate Mapping ✓ ✓ Fluid Front ✓ ✓ Liquid Metal Temperature ✓ ✓ Air/Back Pressure, Vacuum ✗ ✓ Trapped Gas/Oxide Tracking ✗ ✓ Temperature Dependent Material Properties ✗ ✓ Cyclic Thermal Coupling ✗ ✓ Fill Rate/Time Verification ✓ ✓ Single or Multi-Phase Shot Profile ✓ ✓ Moving Shot Sleeve ✗ ✓ -

Post Processor

-

Feature Essentials Advanced Lighting & Shading Options ✓ ✓ Snapshot/Animation Generation ✓ ✓ Model Scene/View ✓ ✓ X-Ray View ✗ ✓

Porosity

By coupling the results of the fluid flow and thermal simulations, the porosity module for high pressure die casting is able to perform advanced analysis of the likely formation of problematic porosity. The inclusion of trapped air, intensification pressure, and cooling rates in porosity measurements allow the software to accurately determine mechanical properties.

Stress & Deformation

Mold distortions must be considered for truly accurate thermal analysis. Castings falling out of tolerance, die life and fatigue, as well as cracking due to the existence of porosity can all be predicted with the use of the stress module. You won't even have to re-mesh as our FEM mesh is entirely compatible with Stress Analysis.