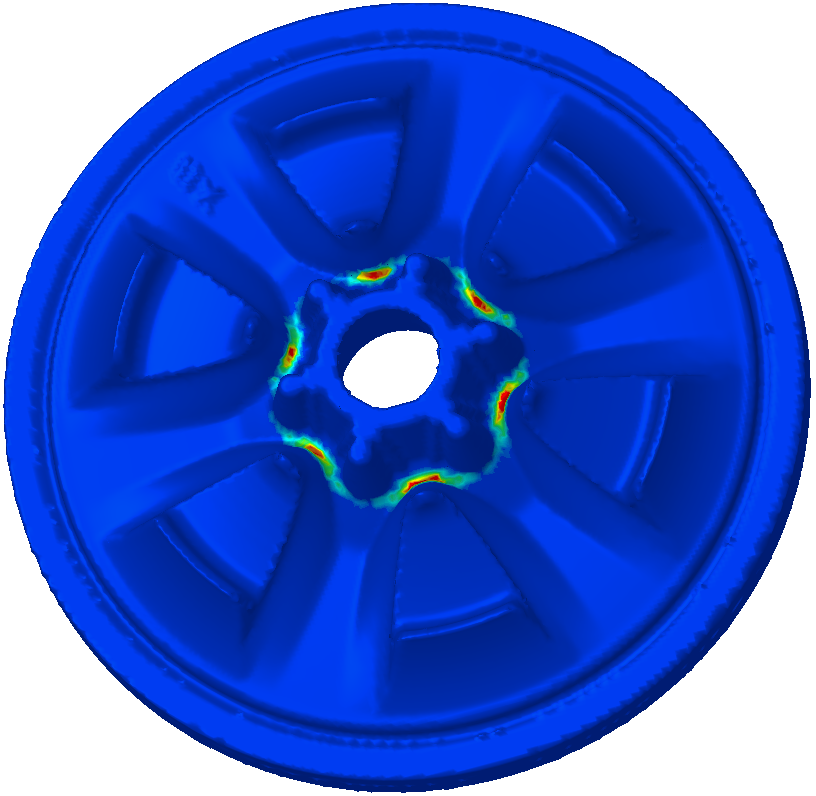

Flash Prediction

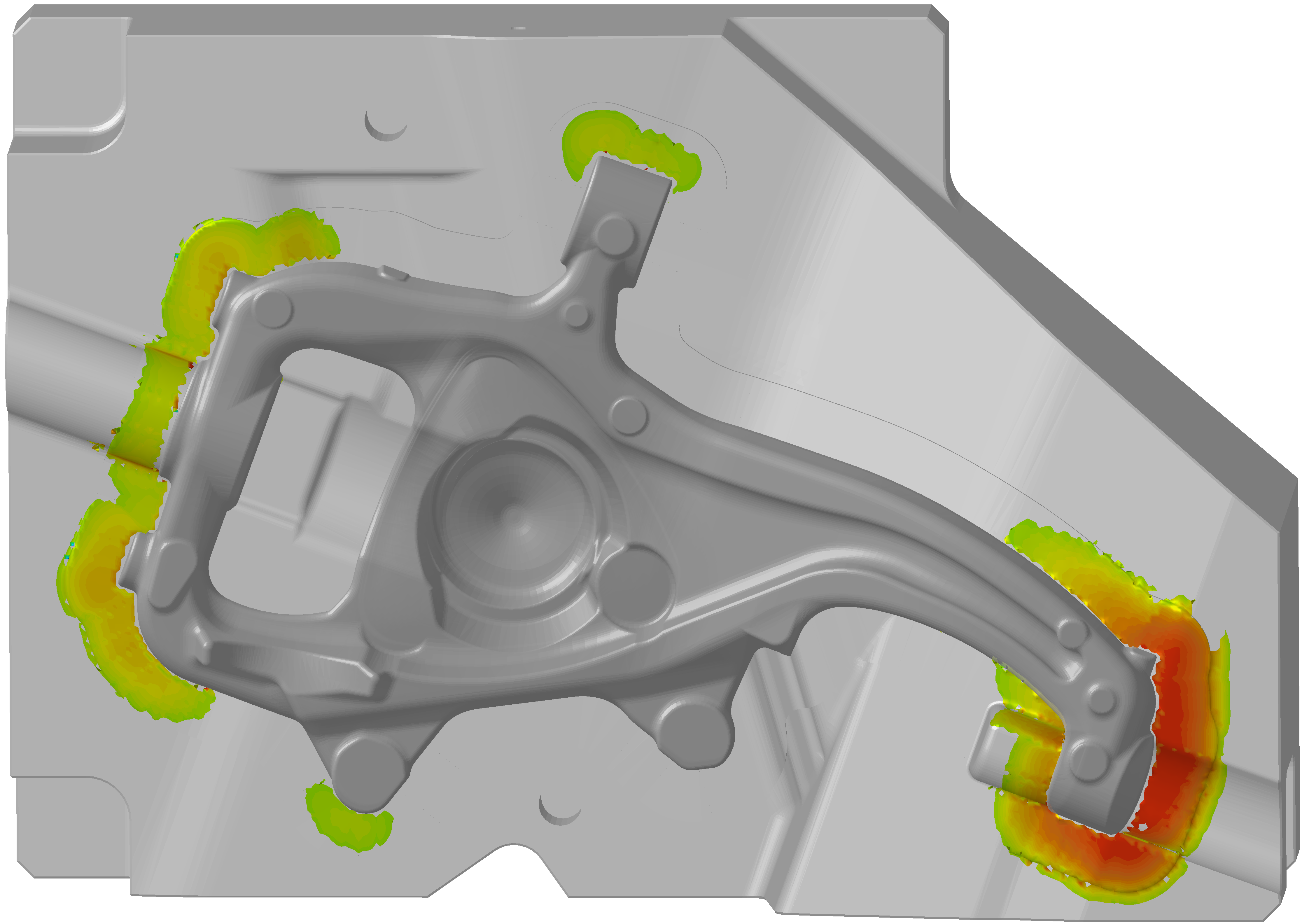

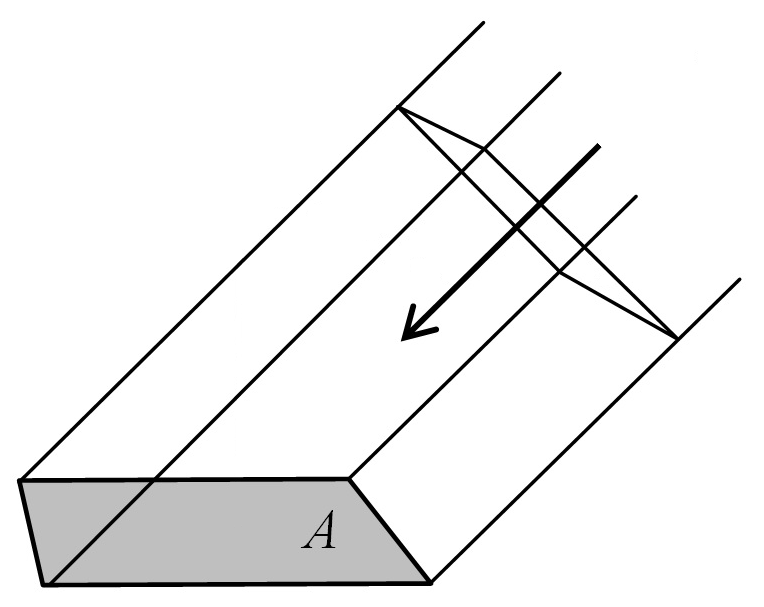

Flash is a common indicator of a variety of issues with a mold design. The success of an initial development process for a casting is often defined by the prevalence of flash. Several costly iterations of re-tooling and machining are often necessary for its elimination.

Designers often utilize Mold Distortion simulations to help minimize or correct for mold distortion, but previously they had been unable to visualize the object of their efforts, the flash itself. By analyzing and aggregating the distortion results for multiple mold components, the software can now directly provide a rendering of the predicted flash.

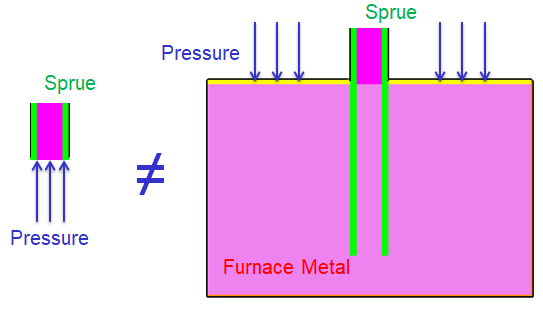

LP Furnace BC

The traditional method for modeling Pressure Curves in Low Pressure simulation assumes that the Pressure can be applied at the bottom of the Sprue instead of to the top of the metal in the furnace, or by substituting it for a Flow Rate.

Recent research indicates that this assumtption is extremely problematic with certain casting geometries. A method has been developed to create and simulate the entire body of furnace metal without incurring exorbitant simulation costs.

Dynamic Cut Plane

Cut planes have long existed in EKKcapcast, but they have been massively overhauled to provide a seamless experience. In addition to a new navigational control element and improved visuals, 3-D Cut mode now allows you to view the interior geometry of the model to provide additional context for the cut plane.

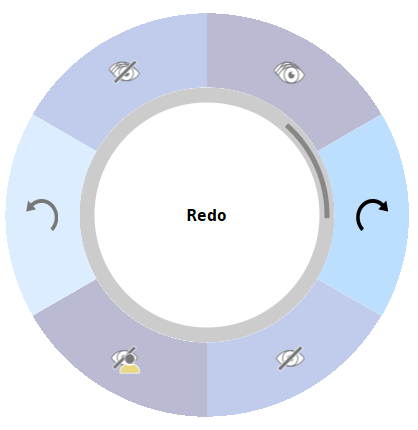

Radial Menus

Radial menus are becoming more prevalent in software for their ability to provide immediate access to popular functions. Just click-and-drag —just like you might swipe on your smartphone— to instantly execute common operations such as hiding components, Undo/Redo, and more.

Navigational Cube

The traditional coordinate axis has been overhauled to provide a significant improvement in the way users can manipulate the model. The cube is interactive; many essential navigational functions can now be applied directly and come with helpful feedback. Important visual cues for the model orientation are visible at a glance.

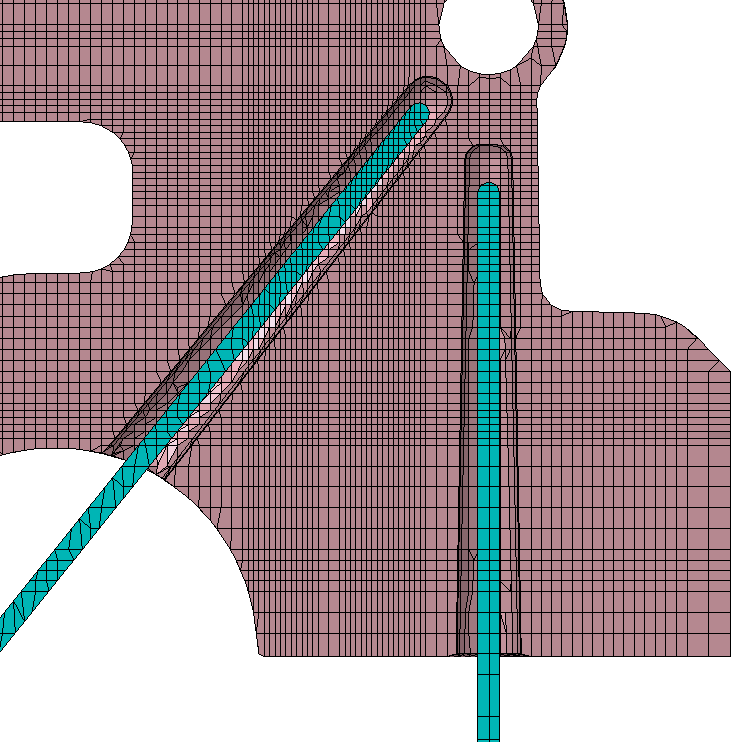

Selective Mesh

KENT can now target specfic CAD components when meshing. These components will be expressly prioritized, making it perfect for challenging geometry such as flash, venting, and even jet water cooling pins. Meshing incrementally offers a number of benefits for meshing demanding CAD: more quickly generate meshes, resolve problematic geometry, and reduce final mesh sizes.

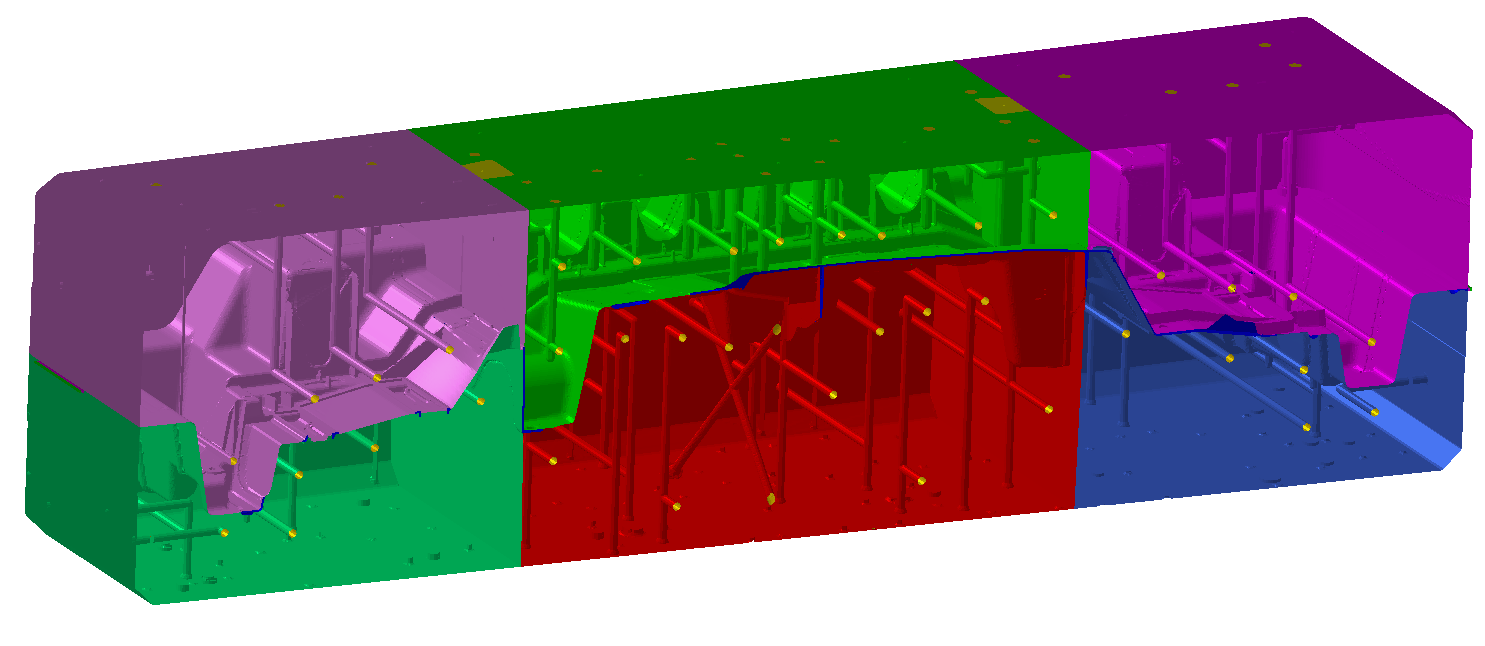

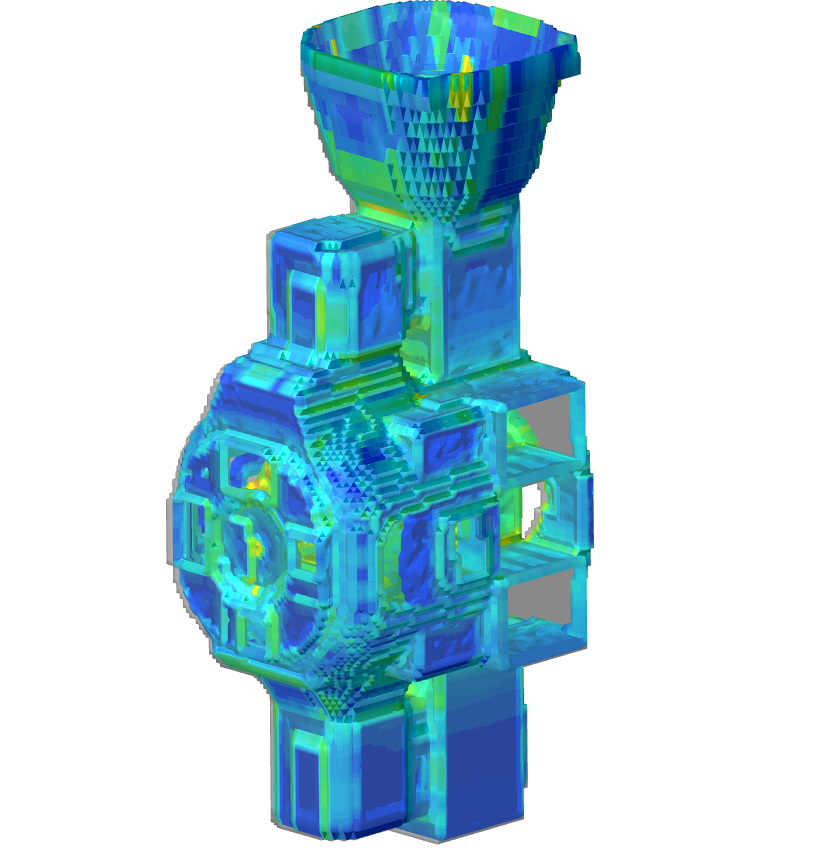

Stress Package Optimizations

A singular FEM Mesh is used for all EKK simulation. This already avoids the error, wasted time, and effort implicit in the process of generating additional stress-compatible meshes. There is also now no practical limit regarding the mesh size for Stress simulation. Alongside other optimizations and improvements, this enables the simulation of even uncoarsened, hefty HPDC die components.

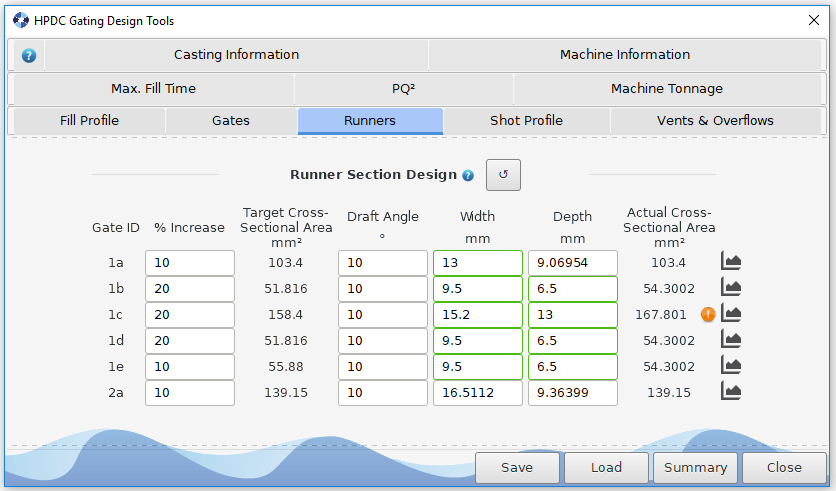

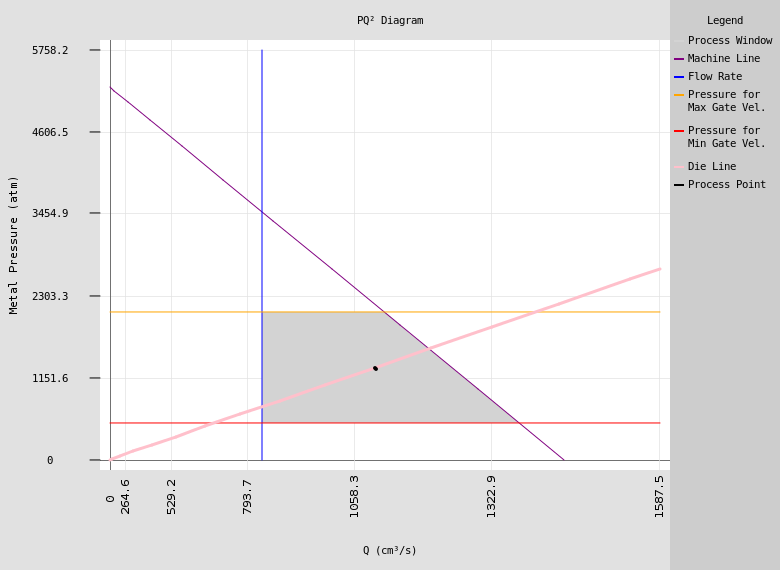

Gating Design Tools

Existing HPDC gating design tools have been consolidated into a comprehensive interface that includes functionality based on industry standards, such as fill time calculation and PQ² Analysis, as well as powerful tools that provide guidance for developing complete runner and overflow systems for your casting. Suggested shot profiles and various 'reality checks' are also provided.

Result Tracker

New interactive tracer functionality allows for results to be tracked at any location in the model after simulation - while reviewing results. Graphs are generated while the animation is playing, providing both useful qualitative and quantitative outputs.

Slow-Fast shot transition visualized

3D Mouse

Those who have used a 3D Mouse in CAD software will tell you how essential they are to a 3D design experience. EKKcapcast now offers support for 3Dconnexion products on Windows™.

6-Point Alignment

By constraining the model according to locators, a variety of insights can be gained into stress results beyond simple displacement. This method for the post-processing of stress results is now availbale for users with the Stress Module.

Radiation View Factor

Calculating the Radiation View Factor is usually a prohibitively lengthy process. EKKcapcast has successfully parallelized this calculation utilizing the GPU, enabling the accurate and rapid simulation of Investment Casting solidification.

Estimated Projected Area

The Projected Area of a part can now be estimated accurately and instantaneously utilizing new techniques.

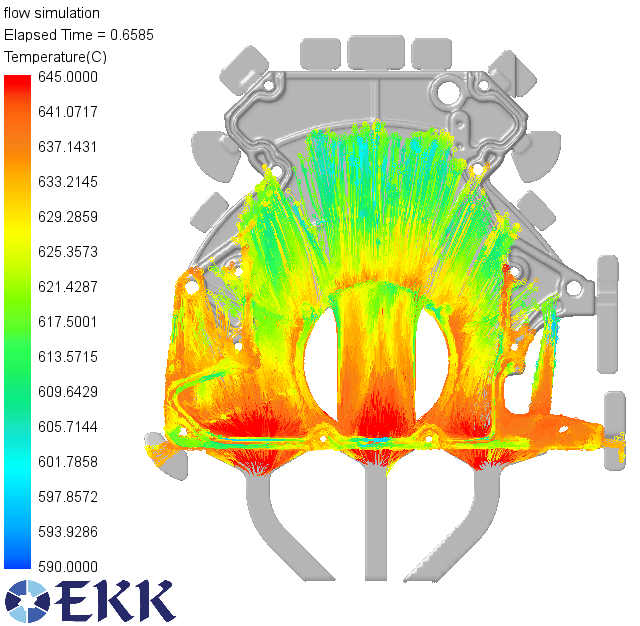

Particle Traced Data w/ Temperature (C)

Revamped Particles

A number of improvements have been made to both the functionality and visualization of particles:

• Effect of Buoyancy on Particles

• Result mapping to particle tracers

• Particle highlighting for easier tracking

New EKKcapcast version!

The new version of EKKcapcast massively improves user experience by offering a feature-rich Integrated Environment. Simulating casting processes has never been easier. Significant graphical and performance updates yield prettier results faster.