The complete package

The only software you need to model every aspect of your casting process and generate a report. Access to a wide range of powerful casting applications in one single window.

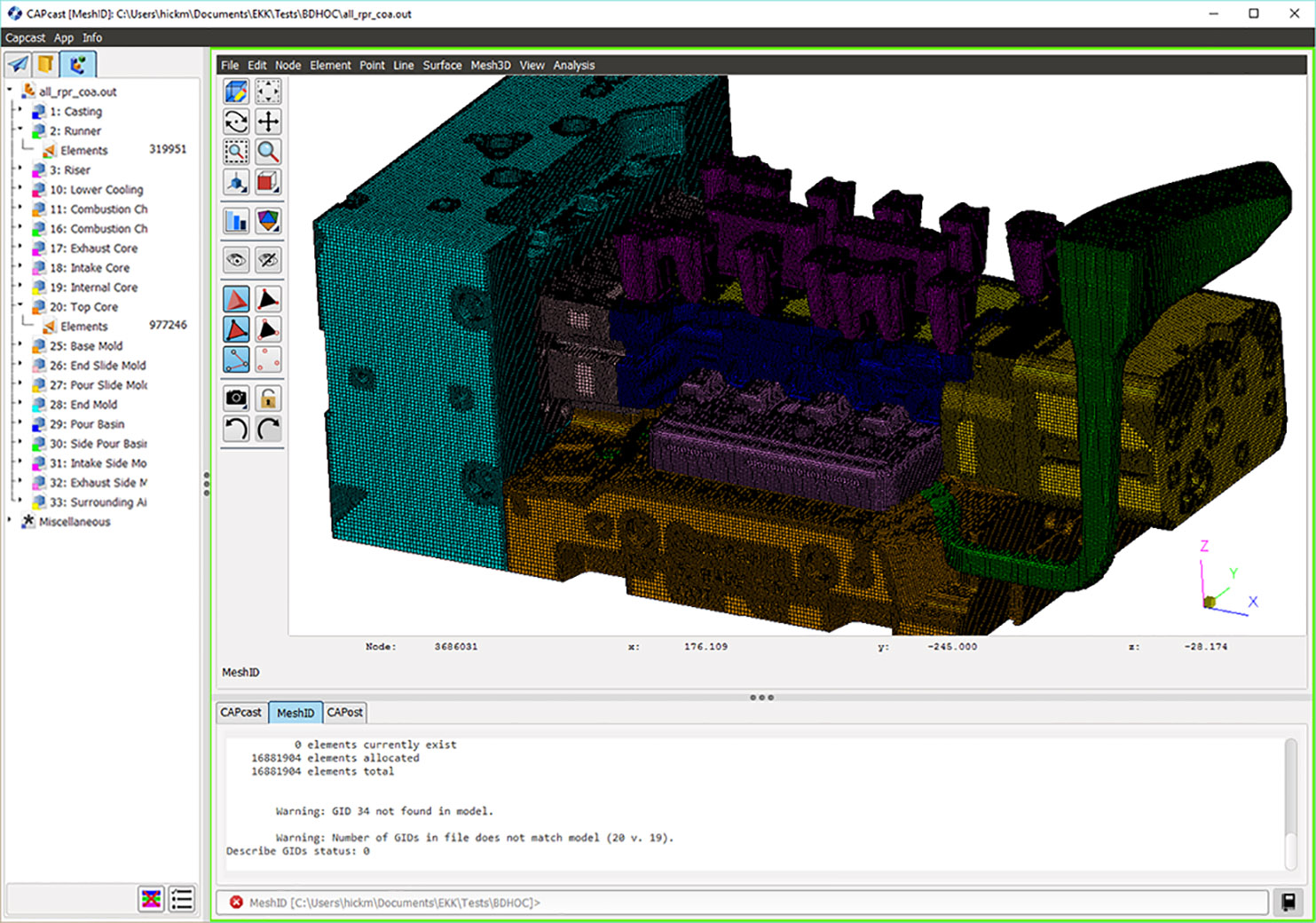

Integrated Environment

EKKcapcast features an integrated environment packed full of everything you need in order to model your casting process.

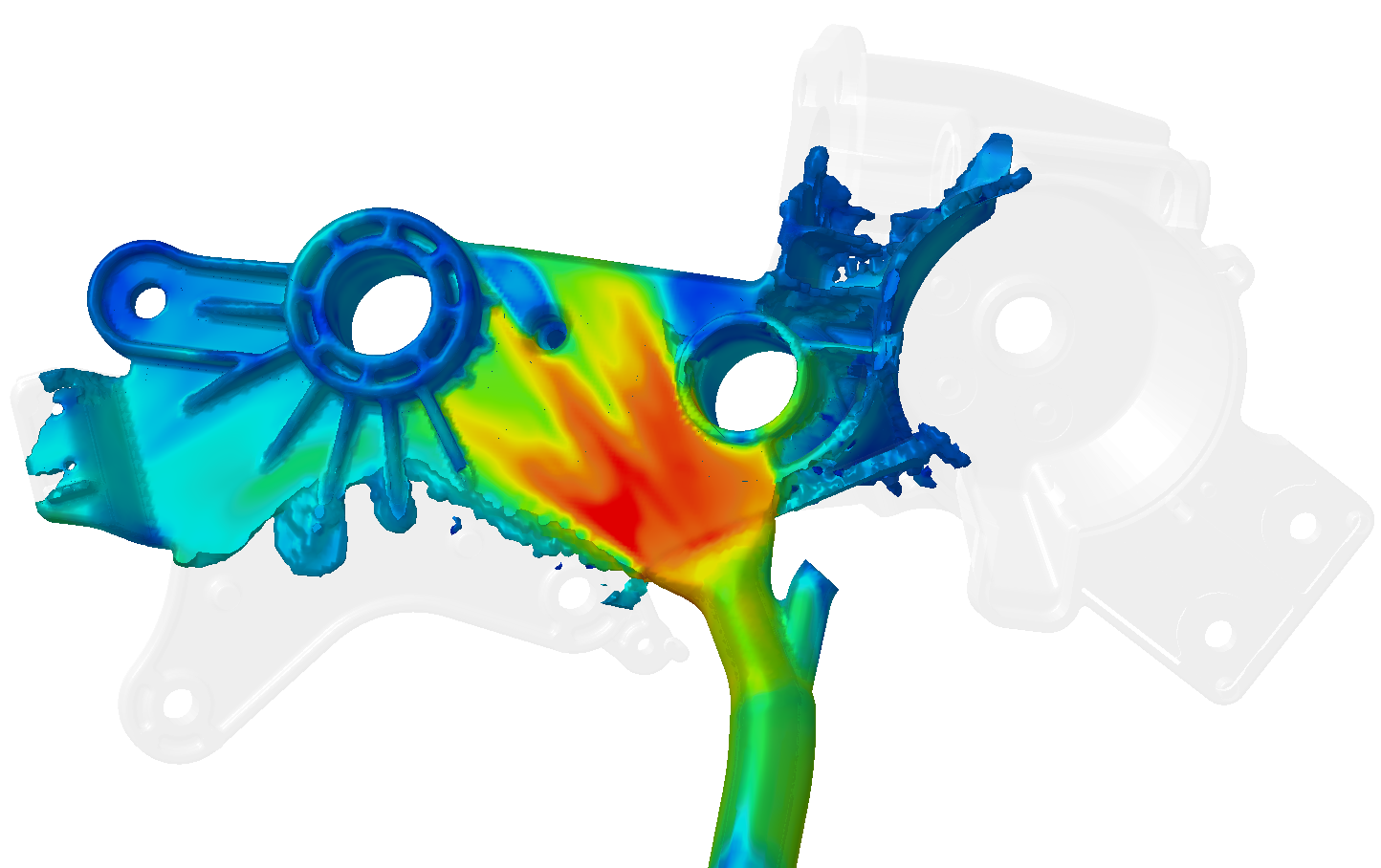

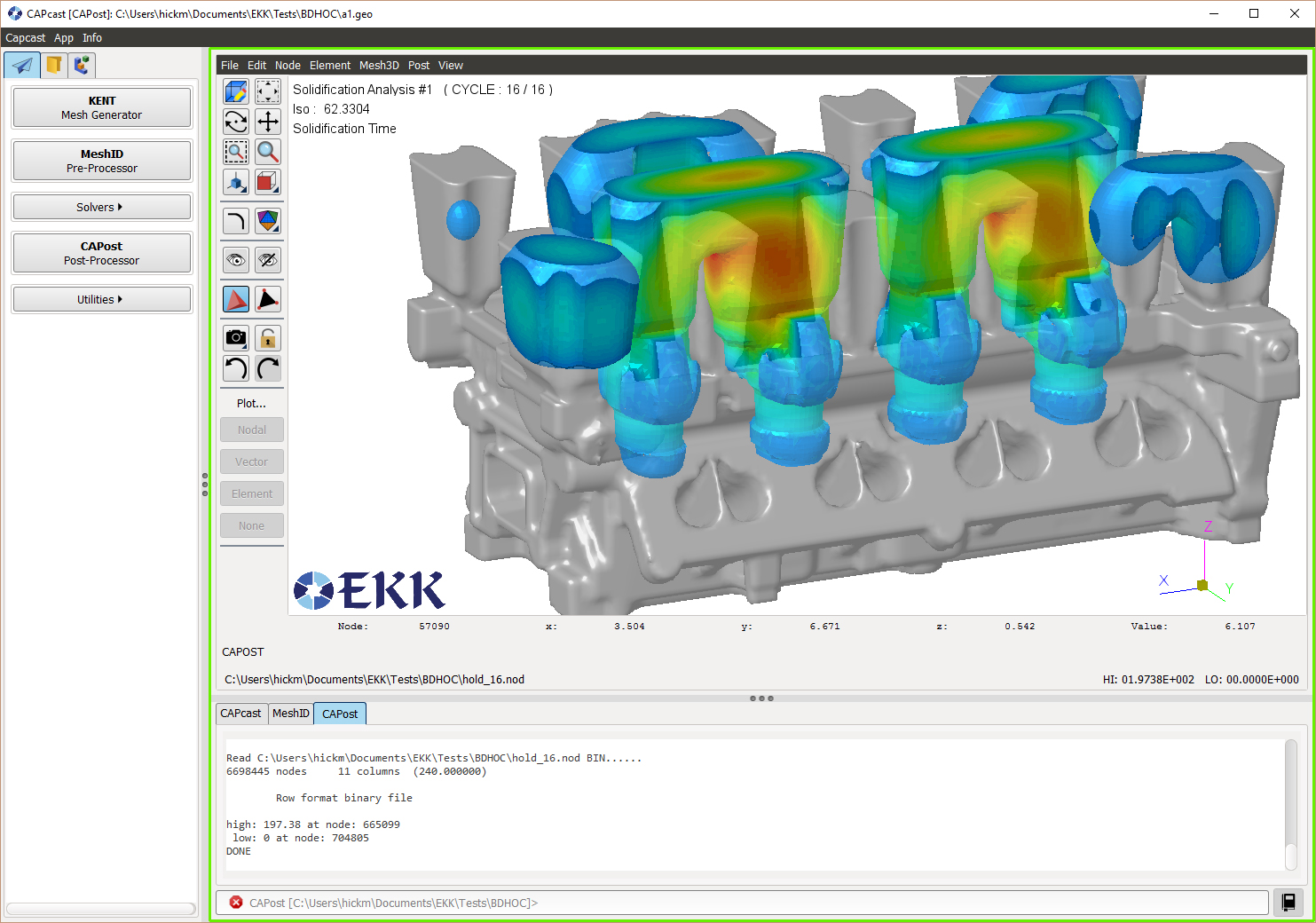

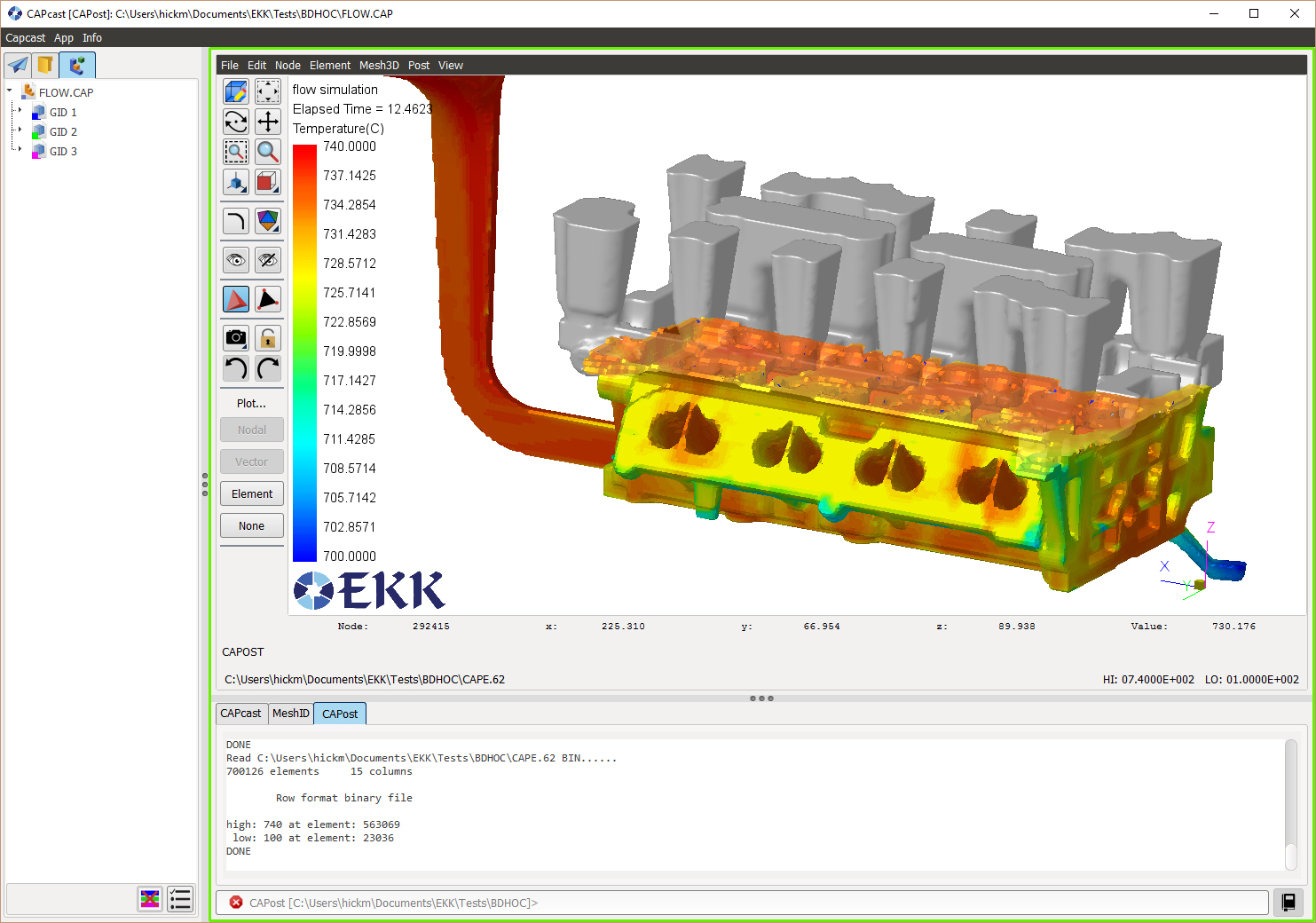

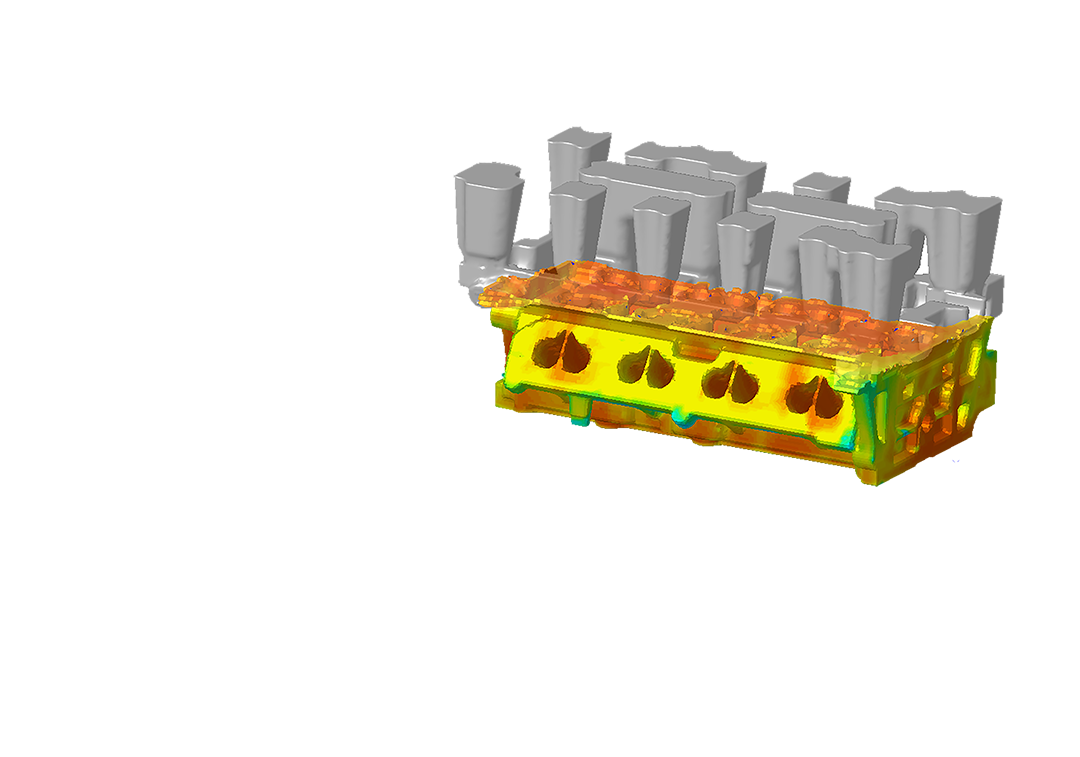

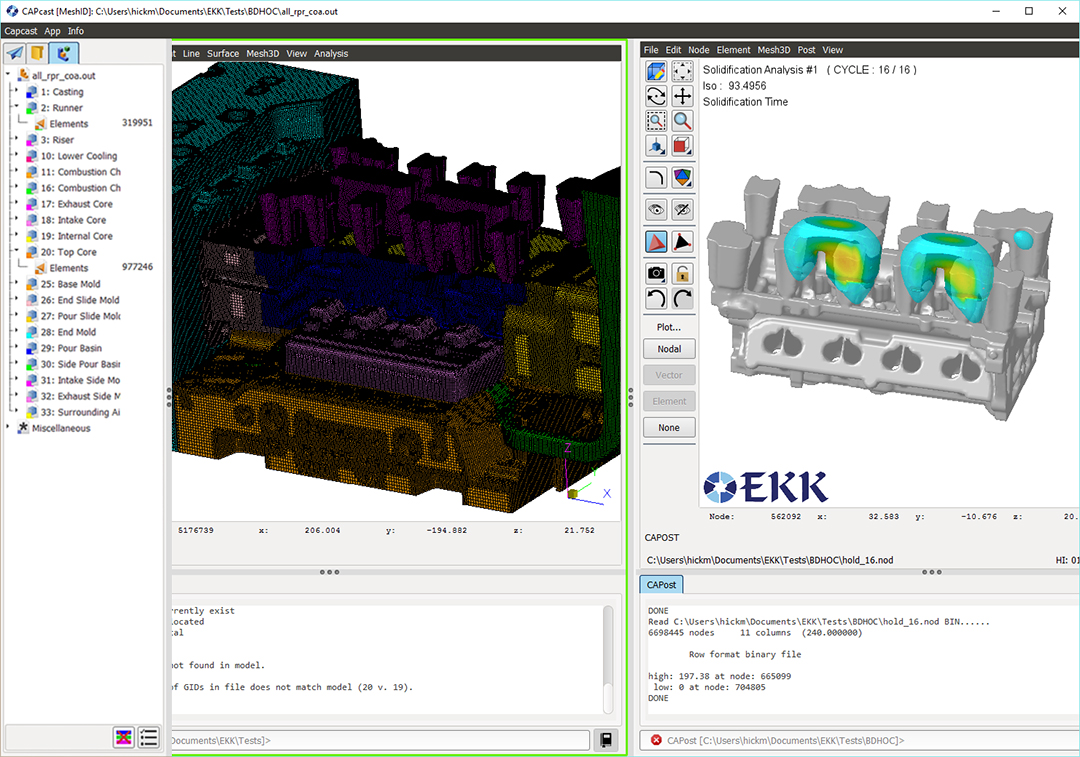

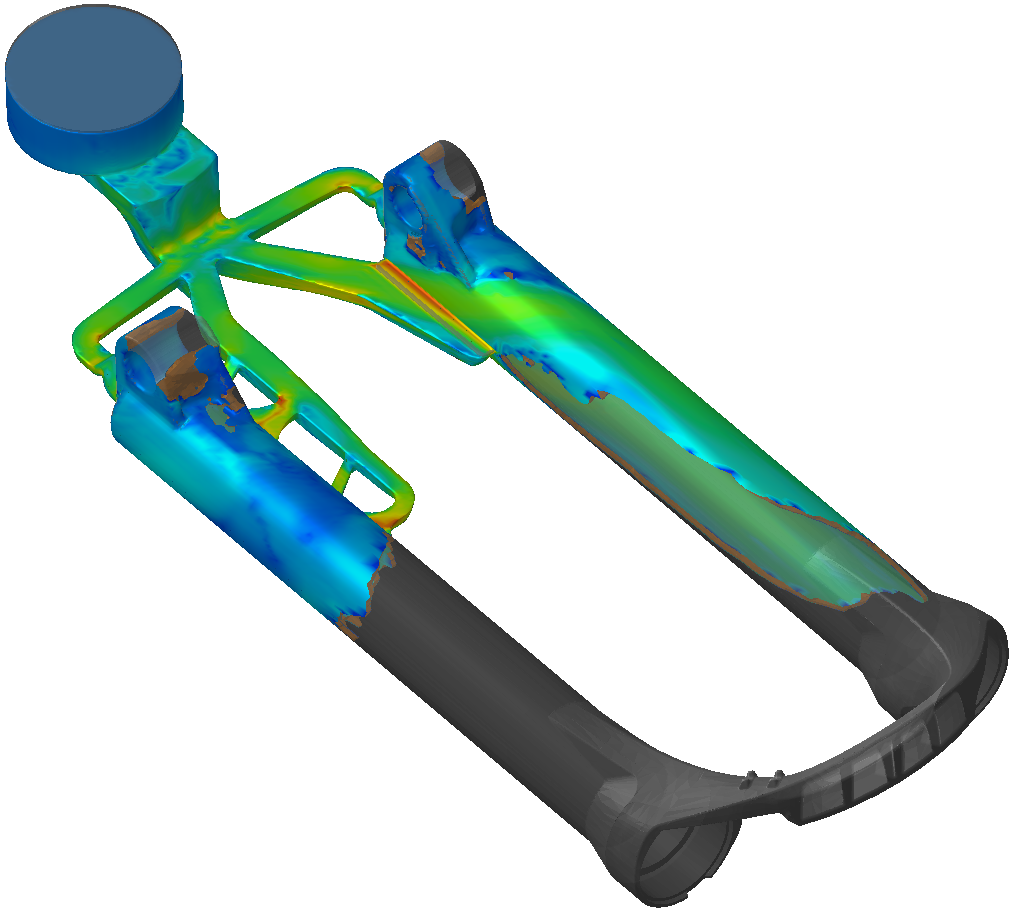

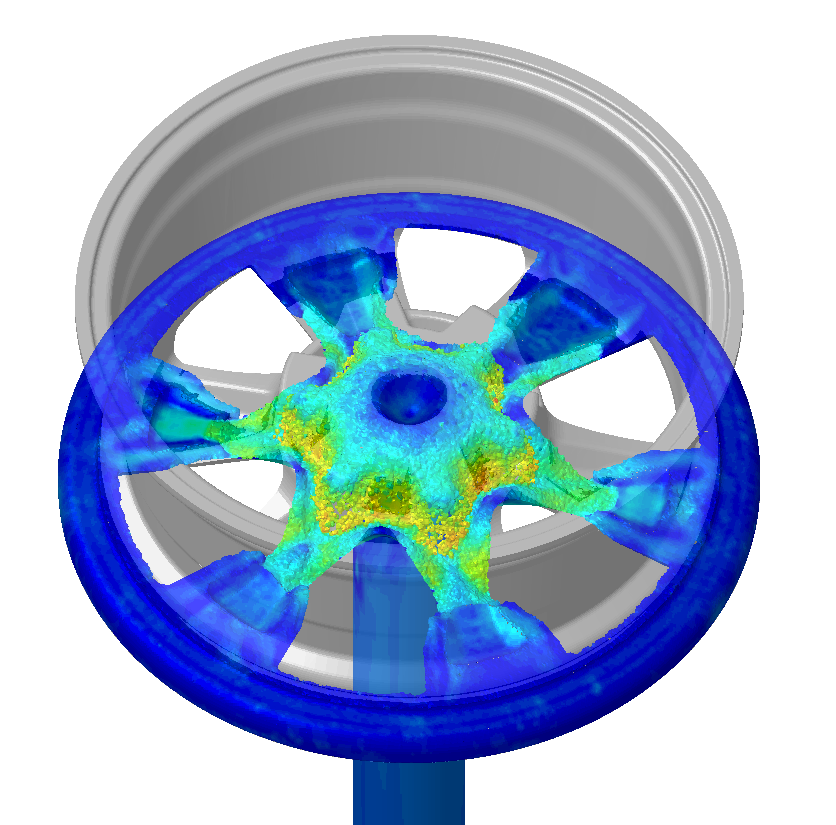

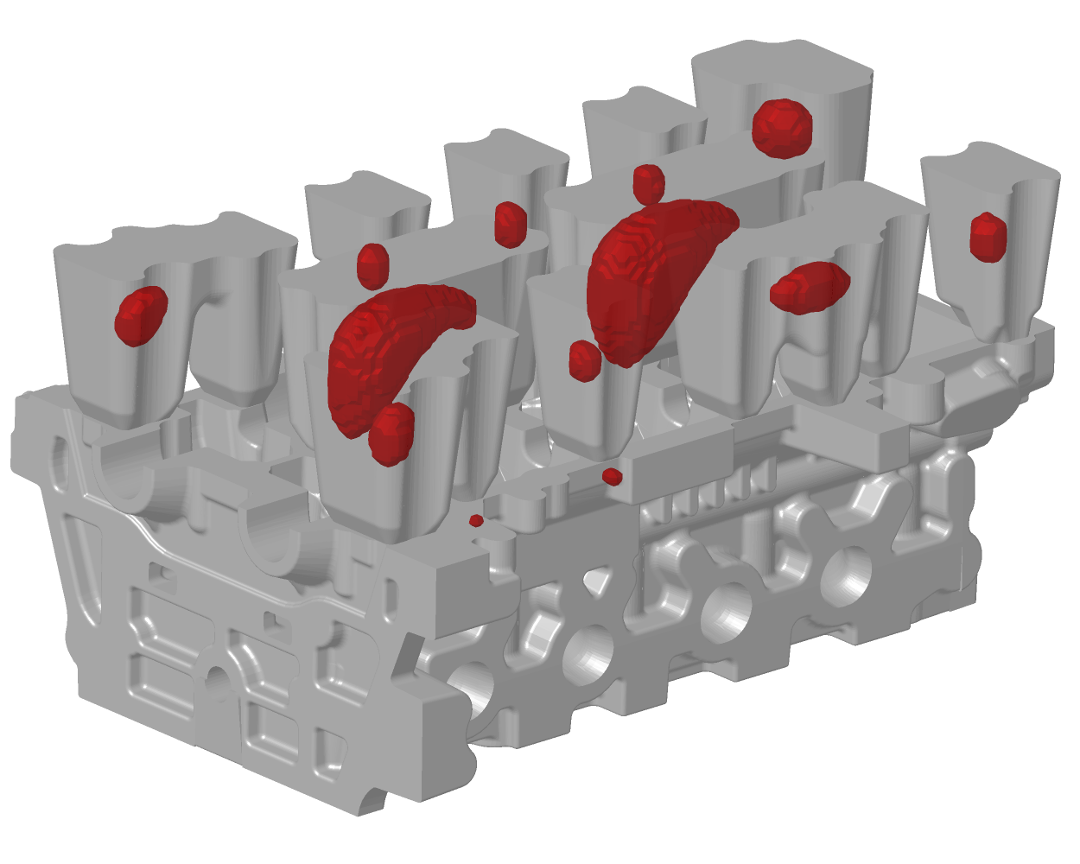

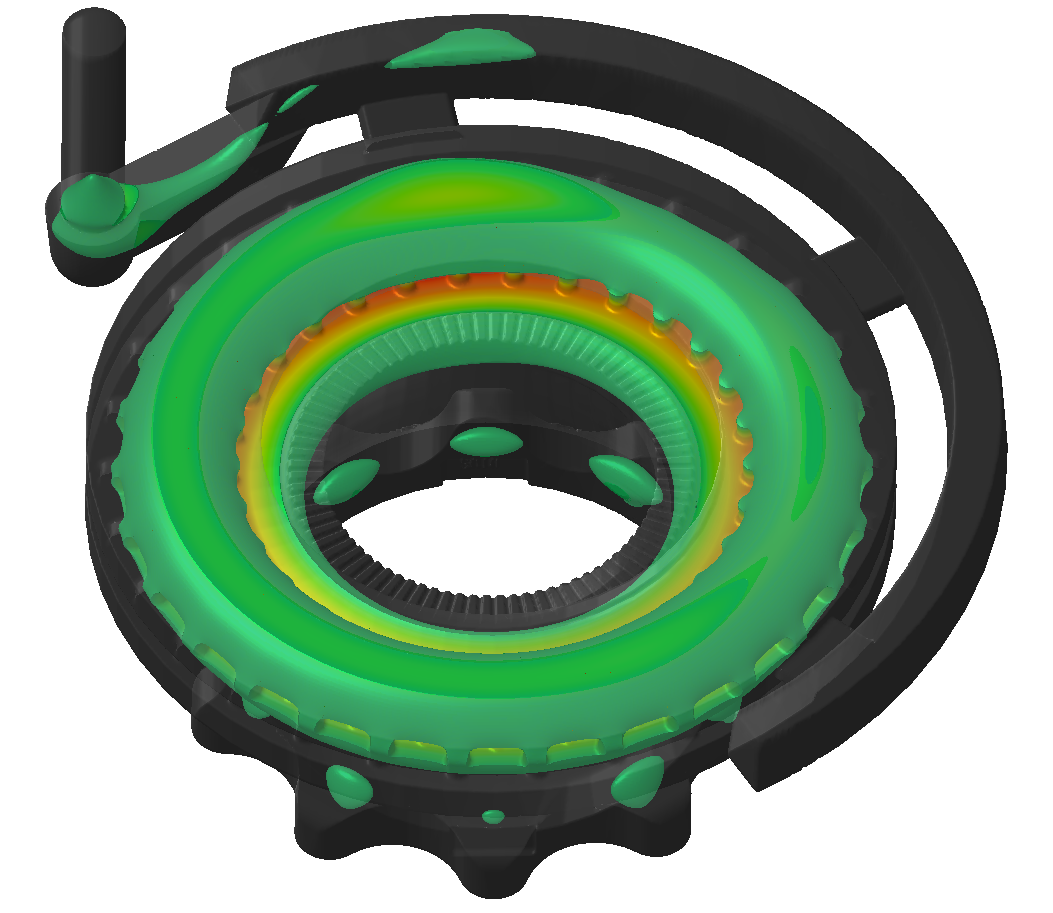

Intuitive results viewer

View models and results quickly and in vivid detail. Easily create report-ready animations and graphics.

Accurate results

Our customers rely on our solvers daily to provide them with a wide range of accurate and insightful data about the casting process.

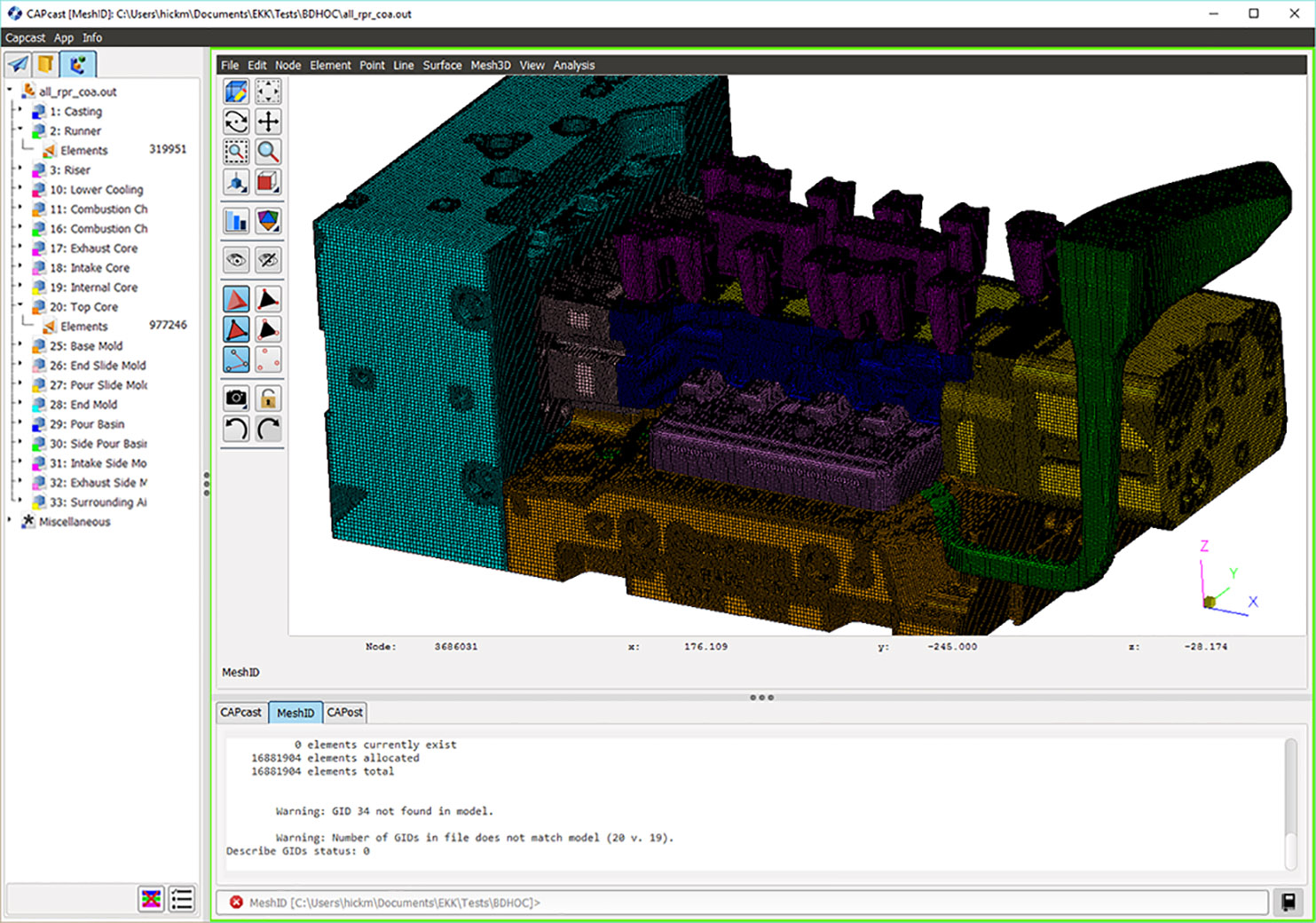

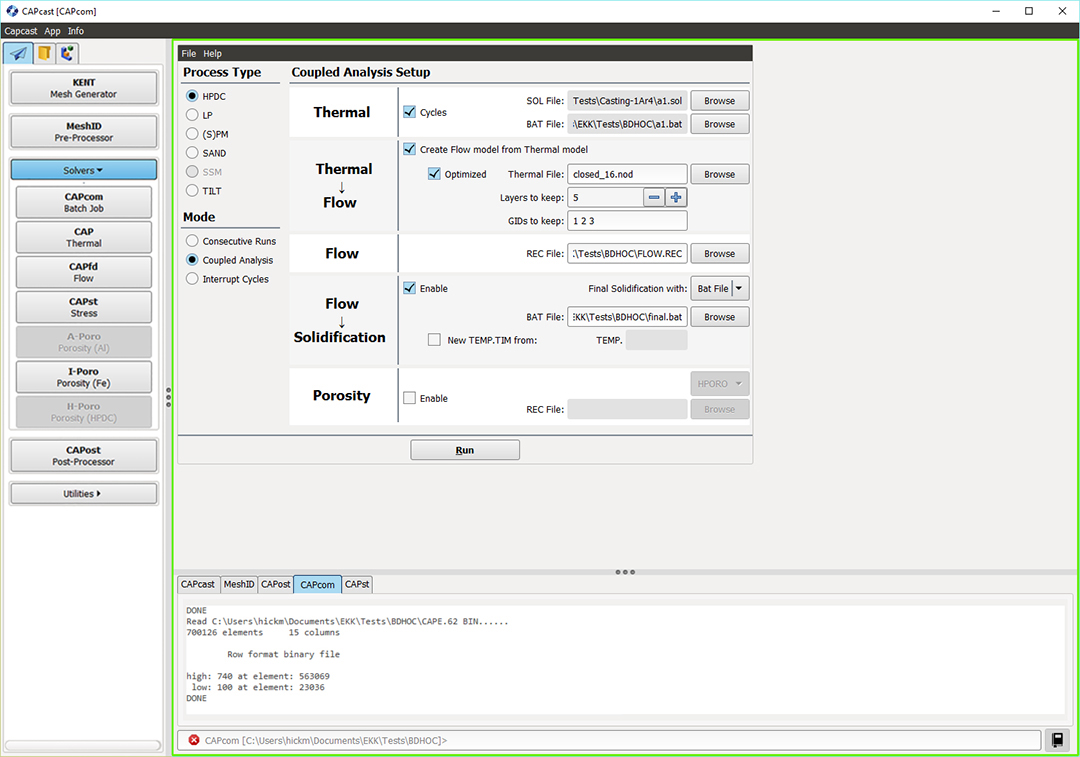

All-In-One Process Setup

Inspect and modify CAD STL, FEM mesh, and other model formats. Use of customizable internal databases enables fast and reliable process setup.

Rapidly Mesh & Alter Models

Meshing is automatic: go from CAD to a down-to-the-millimeter accurate model in minutes. Make adjustments to mesh geometry with an extensive range of specially designed tools and features.

Dynamic

Customize your workspace to fit your needs. Split View modes for side-by-side comparison and improved productivity.

Superior Control & usability

Everything you need to manage your project, model, and simulations. Always accessible and easy to use.

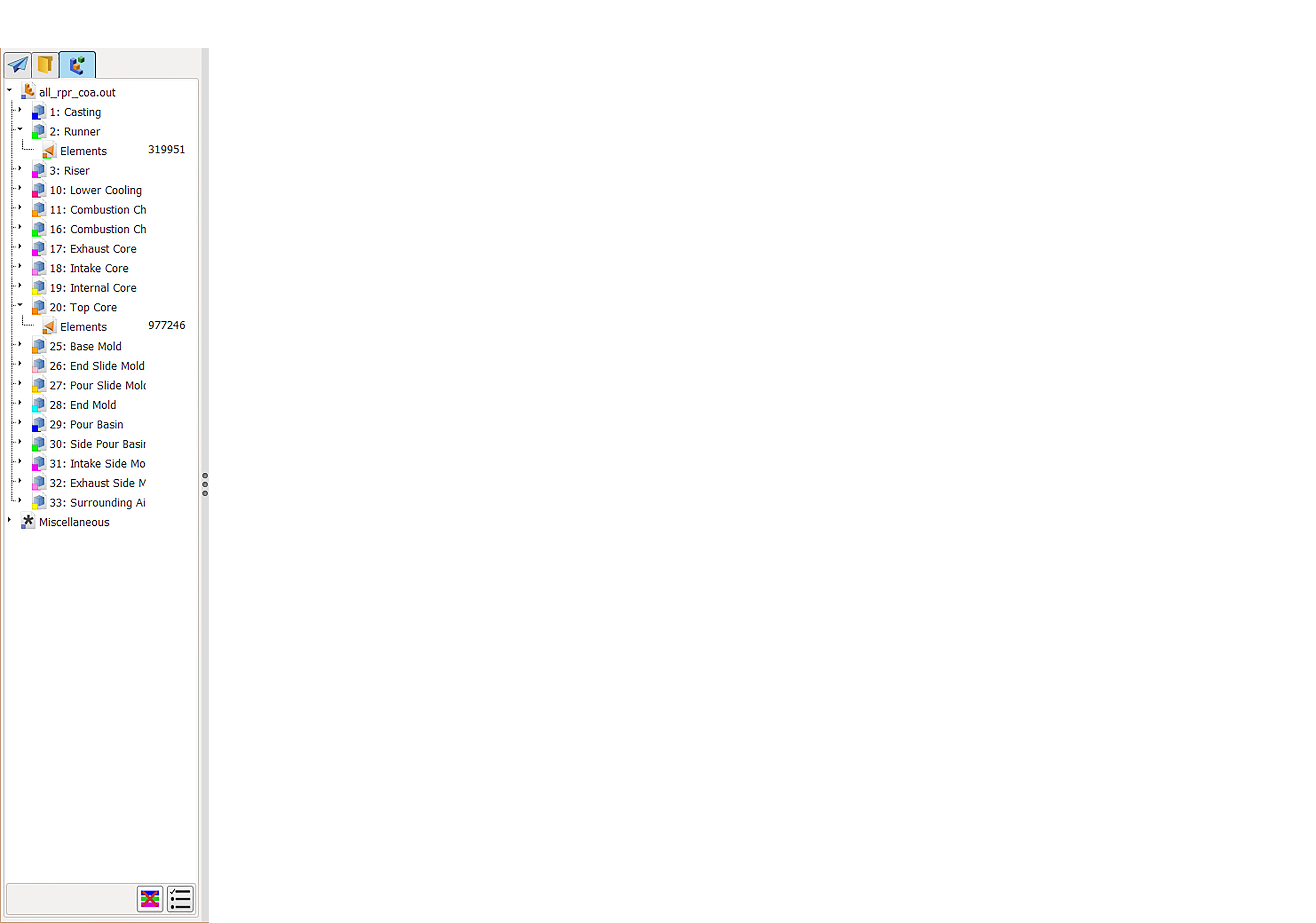

Model Explorer

Act directly on any number of a model's components. Real-time statistics and identifying information.

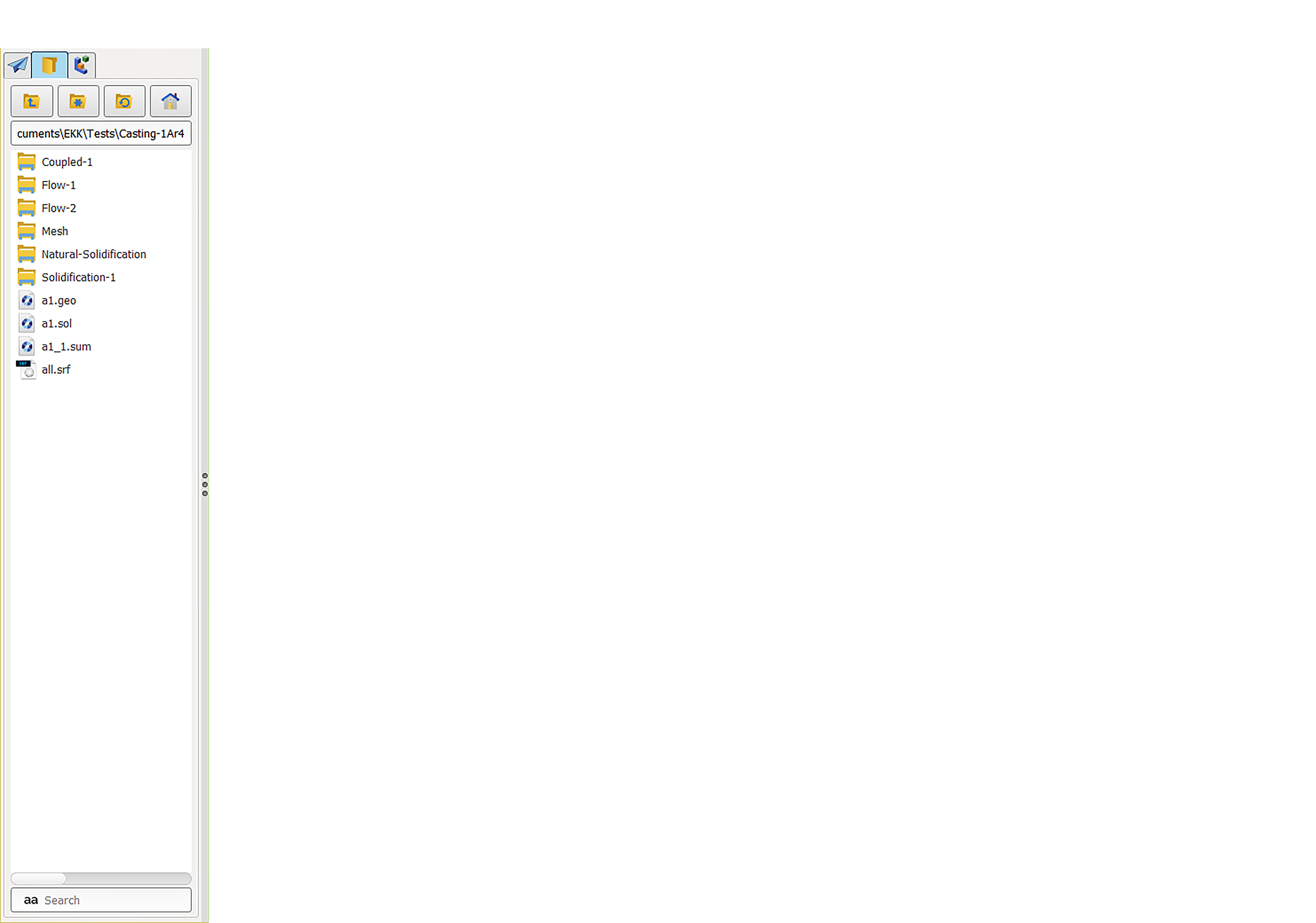

File Explorer

Real-time display and immediate access to the files which make up your project directory. Browse for, edit, and create files on your network.

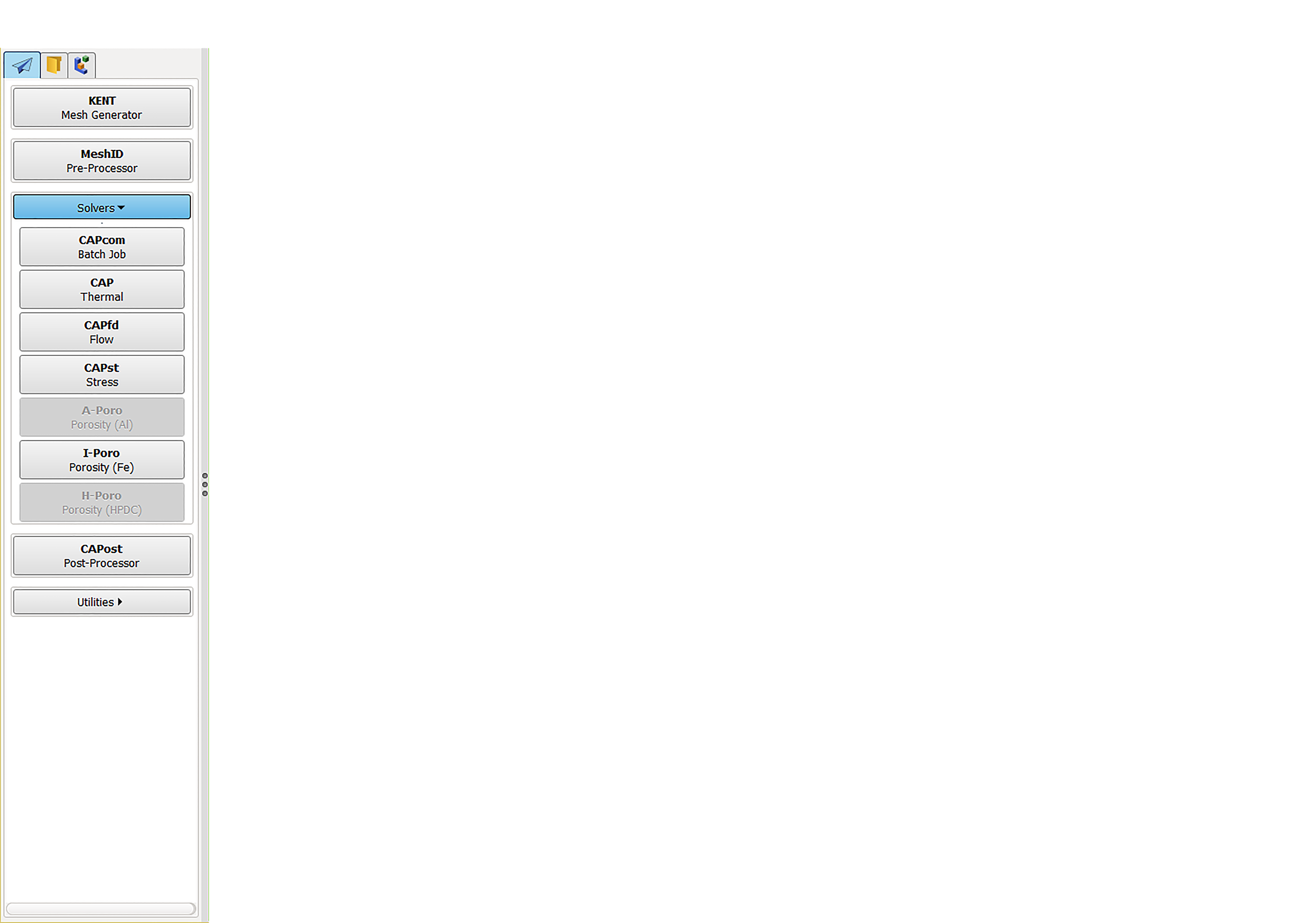

Launcher

The powerful algorithms built into EKKcapcast mean that you will be provided with a wide range of data about your casting process that you can rest assured is accurate.

Advanced solvers

Speed, Accuracy and Efficiency; these are the hallmarks of our solvers. Our FEM mesh models enables significant benefits, allowing the solvers to produce the best results possible in record time.

Integrated output & progress monitoring

Recieve real-time status updates and inspect the progress of your simulations and applications. Results can be analyzed as they are generated.

Supported Processes

Processes

The engineers at EKK, Inc have years of experience working in the casting industry. Our expertise and familiarity with both casting itself and using the software guarantees the best results.

EKKcapcast is a powerful and flexible software, capable of simulating every casting process. Select a process from a sampling on the left for more information. Contact us if you don't see your process listed so we can give you more specific details.

High Pressure Die Casting

The entire casting process is simulated - everything from ladling to die spray. We can design complete runner systems, perform stress analyses on the mold and casting, or simply diagnose problematic flow patterns.

Low Pressure

EKKcapcast's two-phase flow solver is able to use pressure to dictate filling conditions in a variety of configurations making modeling LP, PCPC/ACPC, and VRC/PRC all possible. Real time effects of cooling line configurations can be observed.

SPM & Tilt

Semi-Permanent Mold castings are often quite large and complex making for very demanding simulation work. EKKcapcast is up to the challenge thanks to the advantages offered by our specially designed FEM mesh generator. With moving model capabilities, Tilt pour flow can be easily and accurately modeled.

Sand Casting

The solidification module was the first EKK Inc. developed over 25 years ago. Advances since have only led to reduced simulation time and improved accuracy. Real time effects of chills on solidification patterns can be observed.

Other Processes

EKKcapcast simulation software can be used for modeling other casting processes in addition to HPDC, LP, SPM, and Sand castings. Our mesh generator can be applied to any casting process.