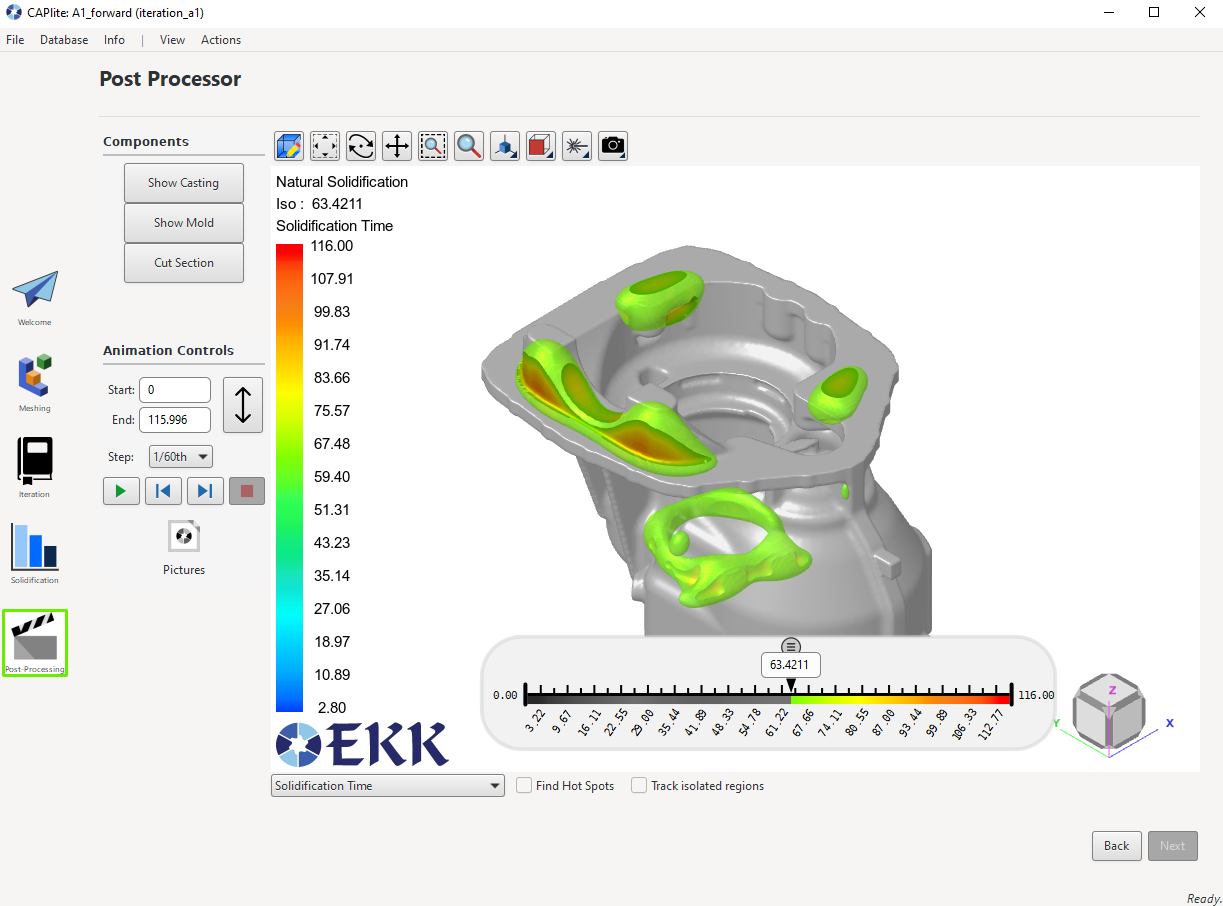

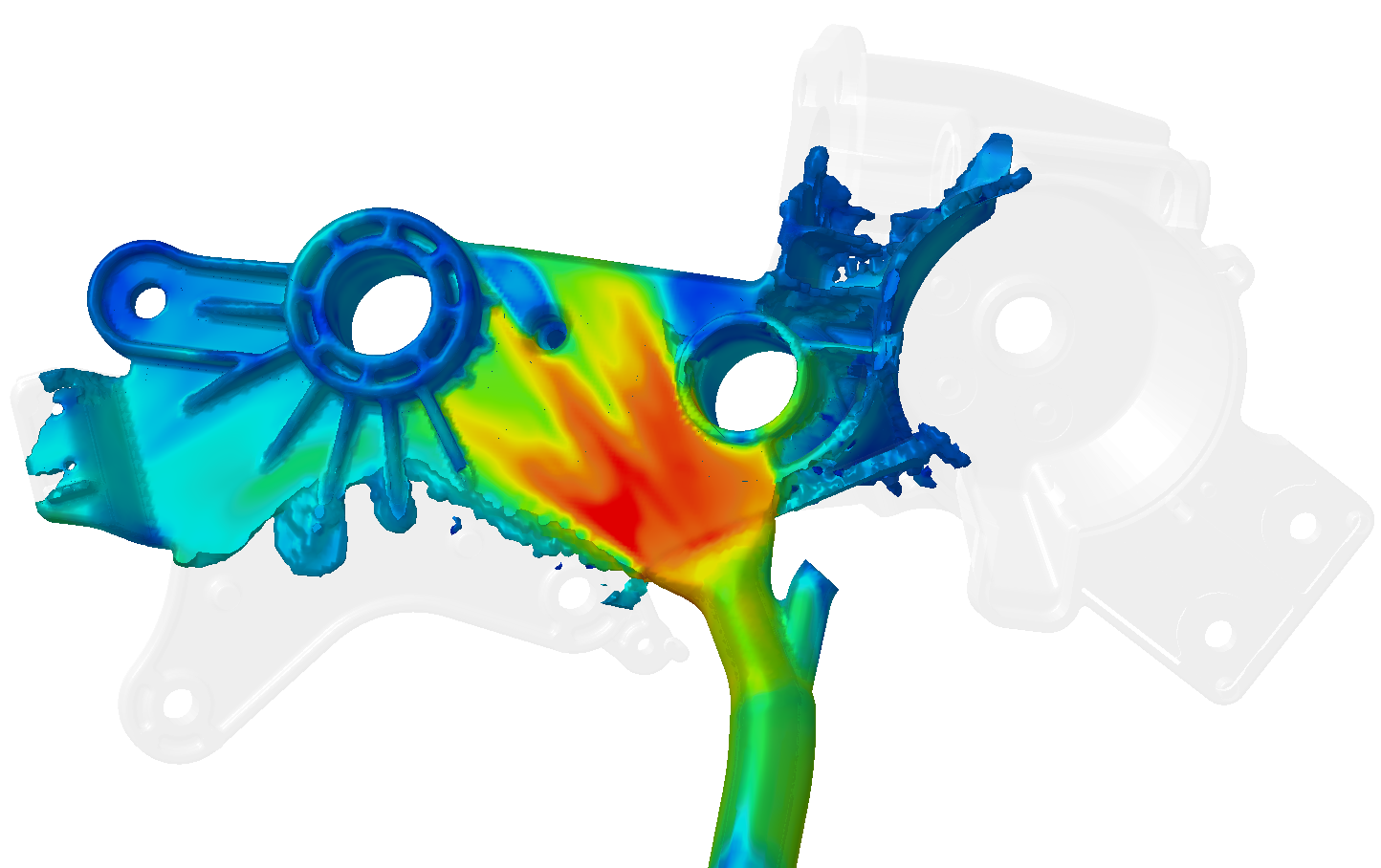

Post Setup now Available!

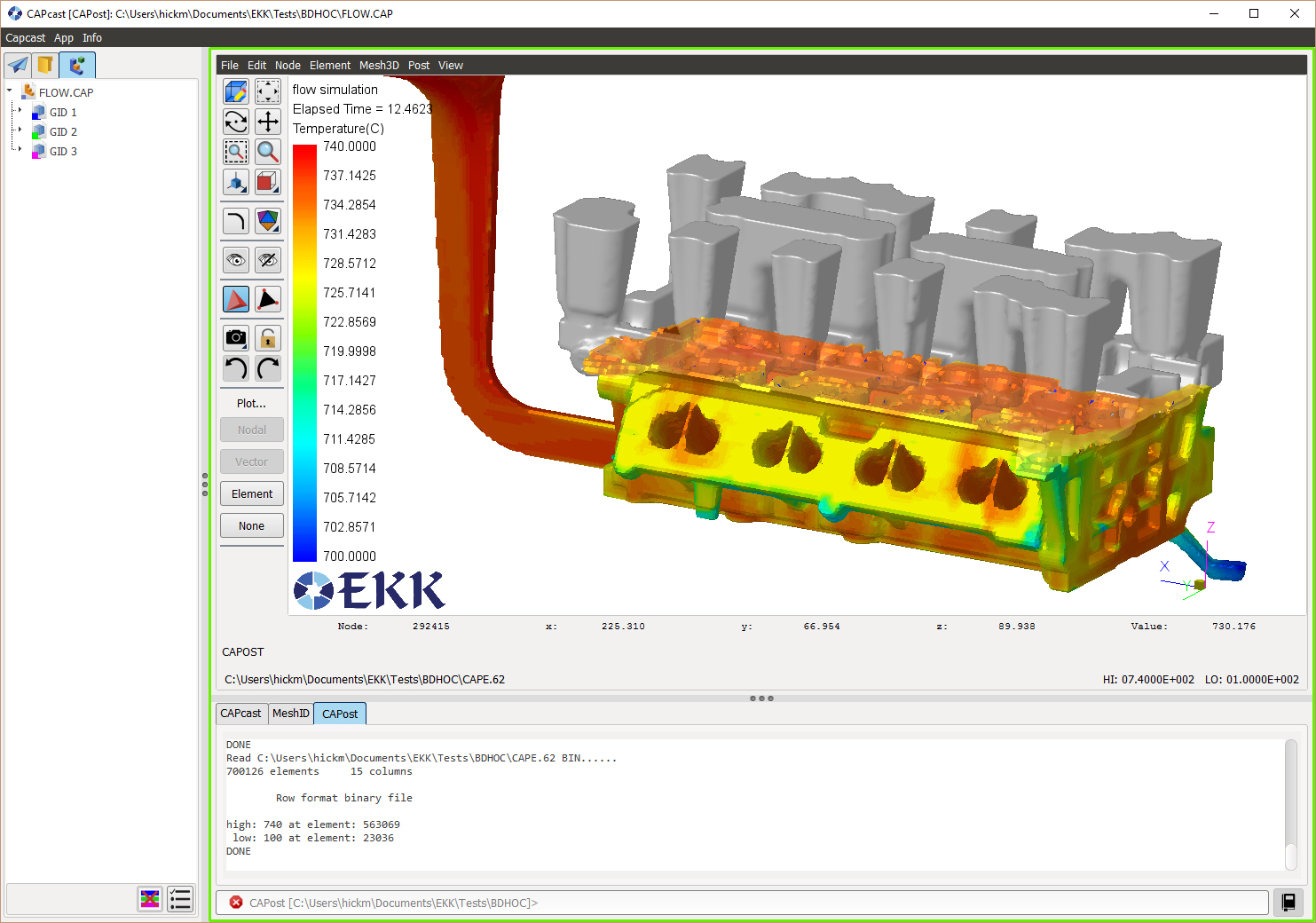

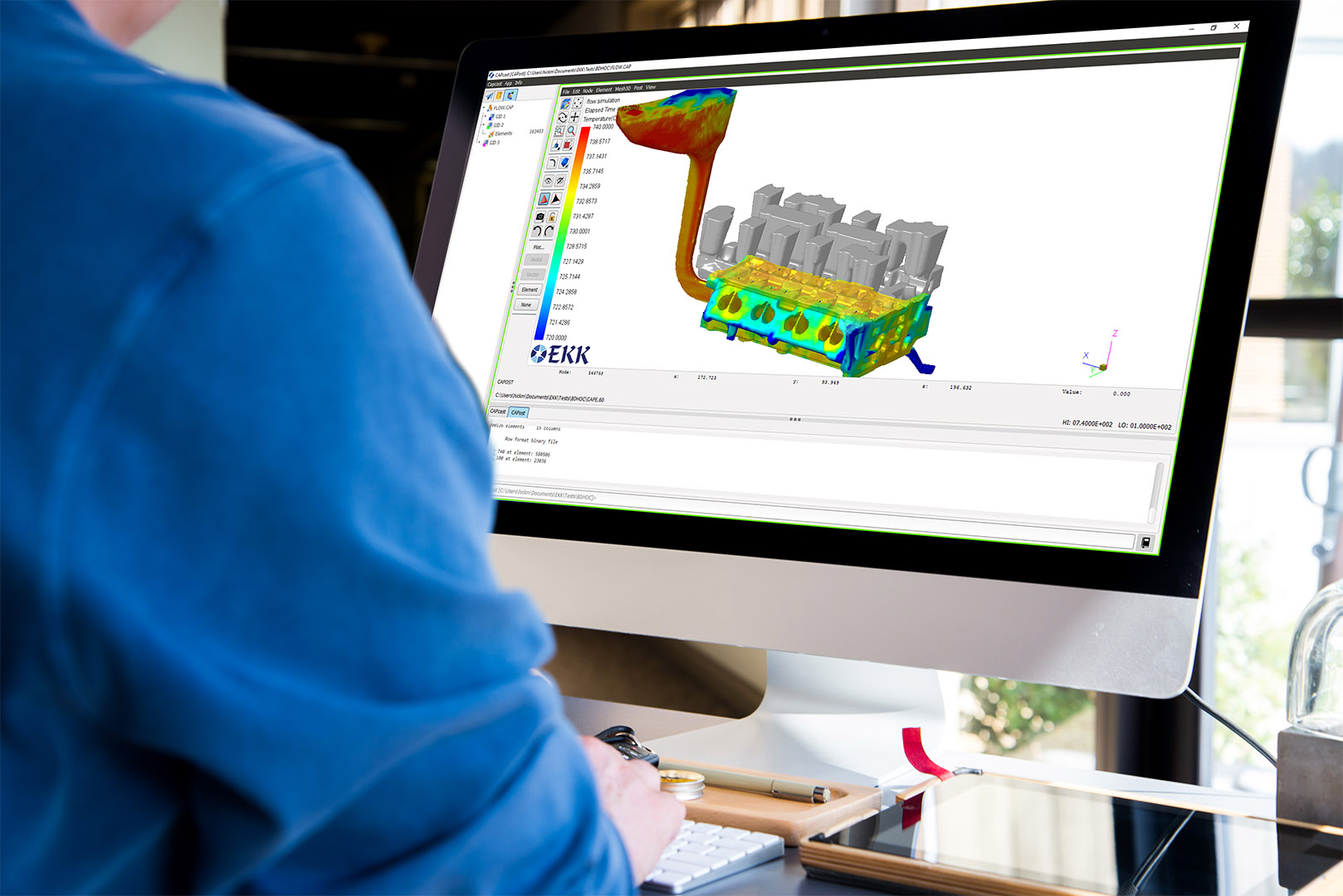

EKKcapcast has a new, revamped method of plotting simulation results for animations and pictures. Want to have someone use EKK who isn't trained? No problem! Post Setup makes post processing a snap!

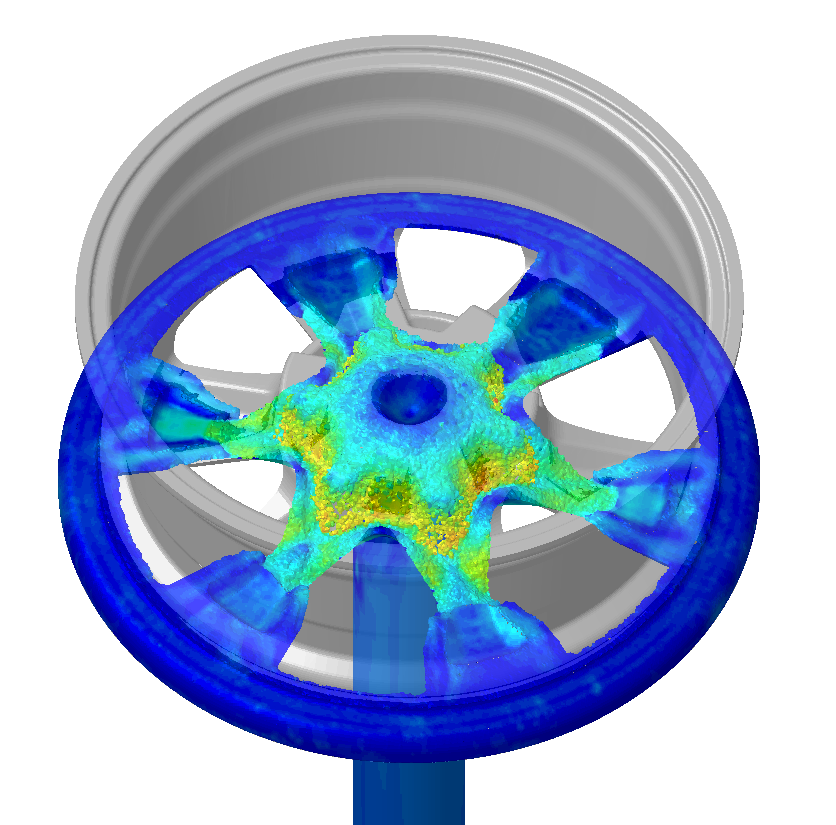

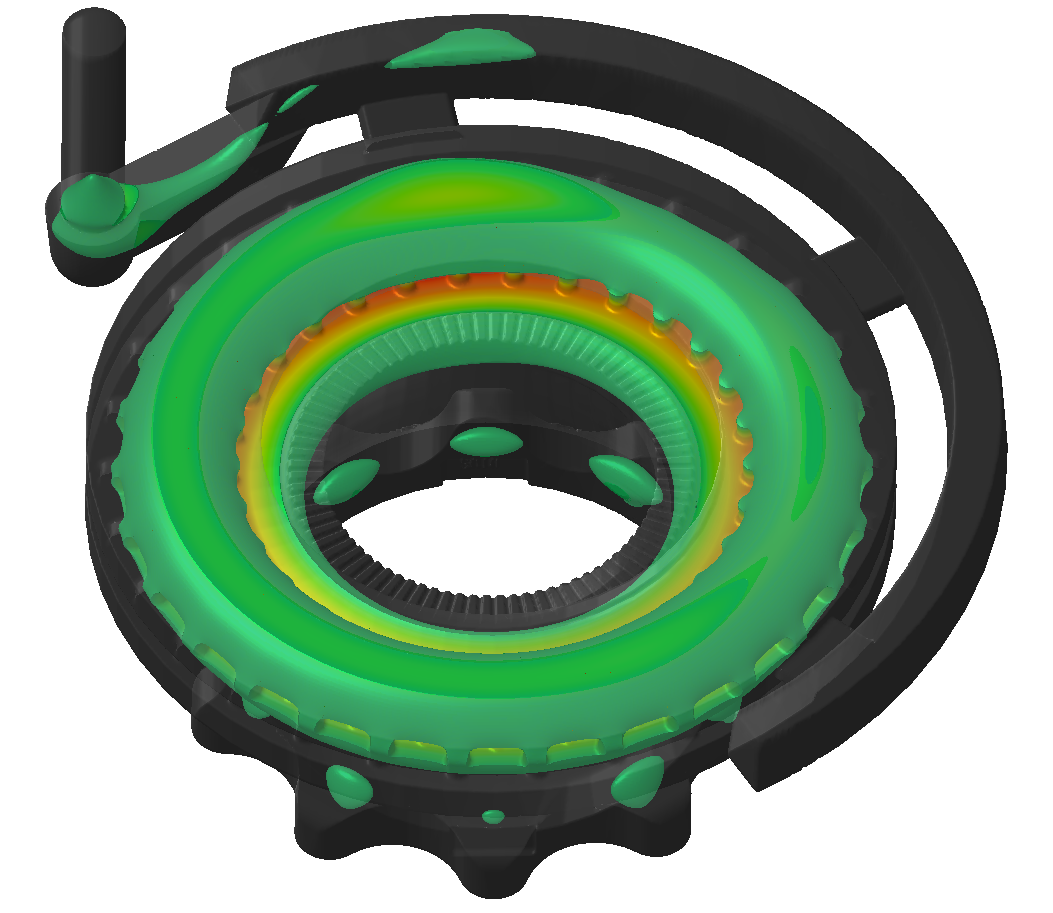

Simulate Cooling Media Flow with EKKcapcast

New technology and research now allows for directly simulating cooling lines and their water flows. This allows for directly determining their efficacy to determine the effectiveness of cooling line layouts.

Visit our Booth!

Want to see what we can do in-person? Come visit us at the 2025 Die Casting Congress & Tabletop!

| NADCA: | October 7-9, 2025 | Booth 234 |

What We Do

Software Solutions

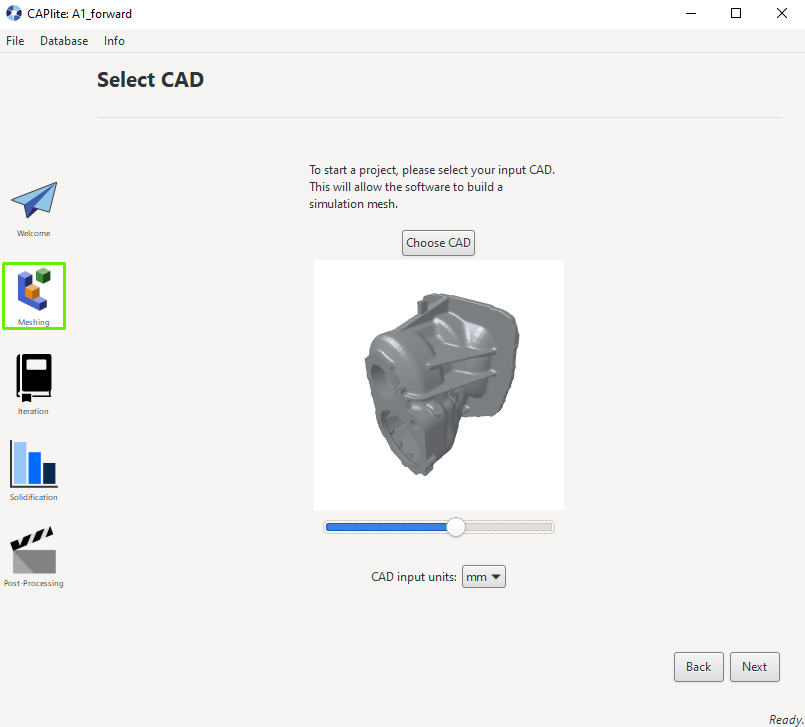

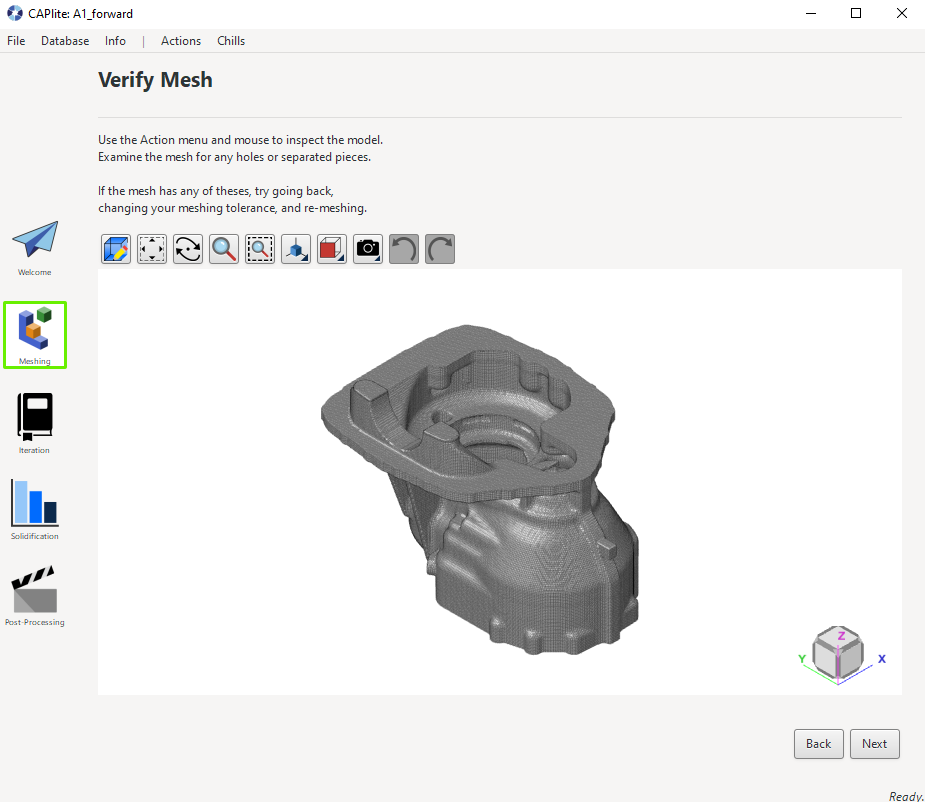

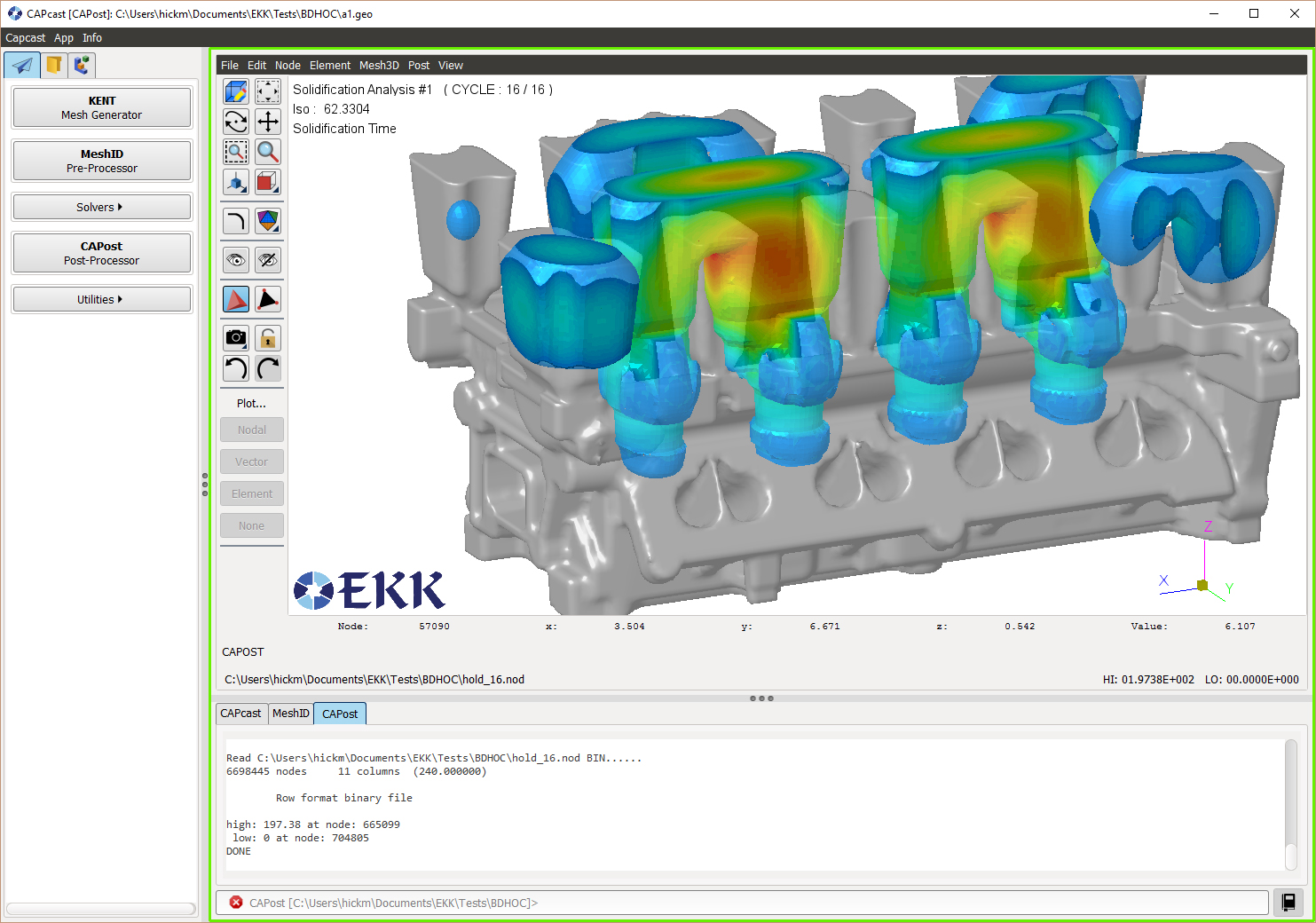

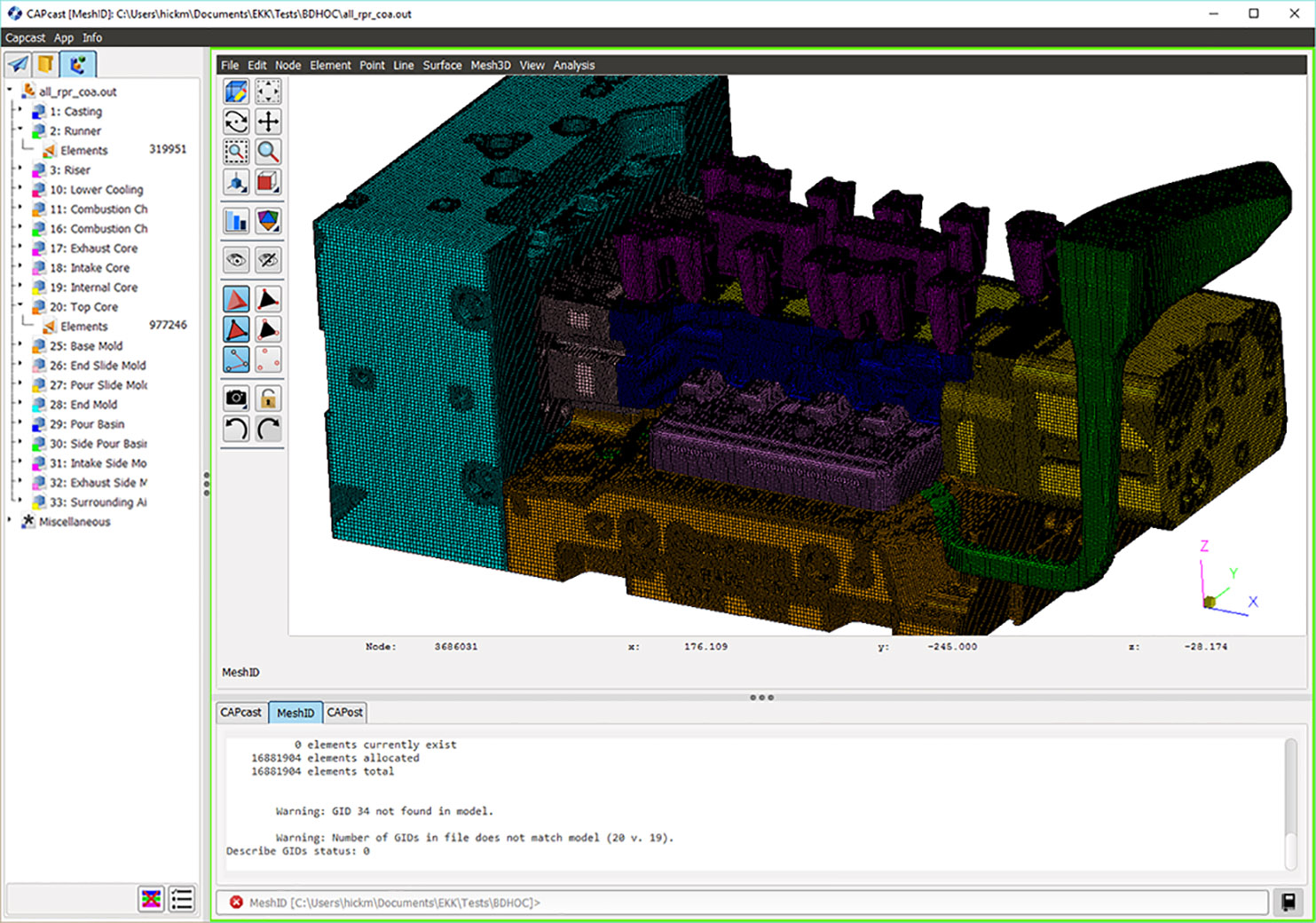

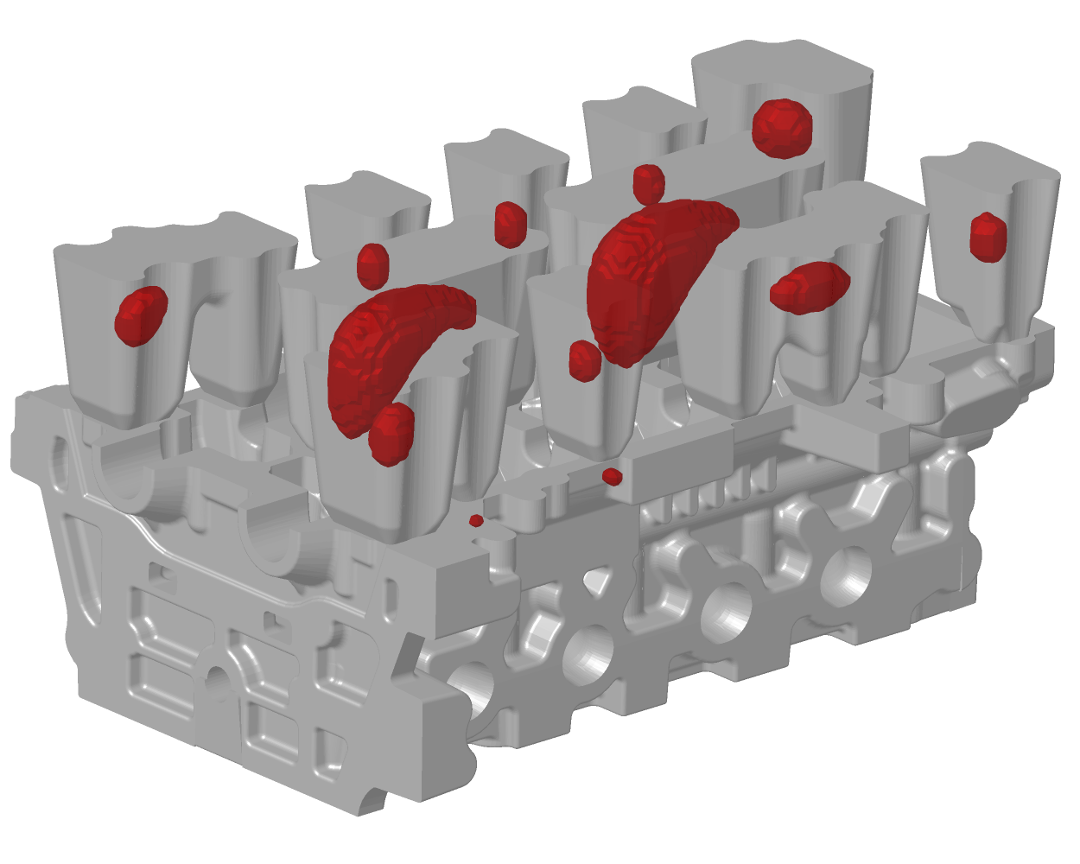

The engineers at EKK have developed EKKcapcast, a revolutionary and sophisticated program for simulating every aspect of the casting process and returning comprehensive and accurate results.

Consulting Services

The engineers at EKK have over 15 years of experience applying EKKcapcast metal casting simulation software to a wide variety of casting concerns.

Cutting Edge Software

Fast

Quick simulation turn around time provides more time for trying out engineering design changes.

Accurate

EKK's Finite Element Method (FEM) based software accurately models your entire casting process using minimal computational requirements.

Efficient

Complex multiple cavity models can be run on modest desktop computers running Linux or Microsoft Windows.

Processes

The engineers at EKK, Inc have years of experience working in the casting industry. Our expertise and familiarity with both casting itself and using the software guarantees the best results.

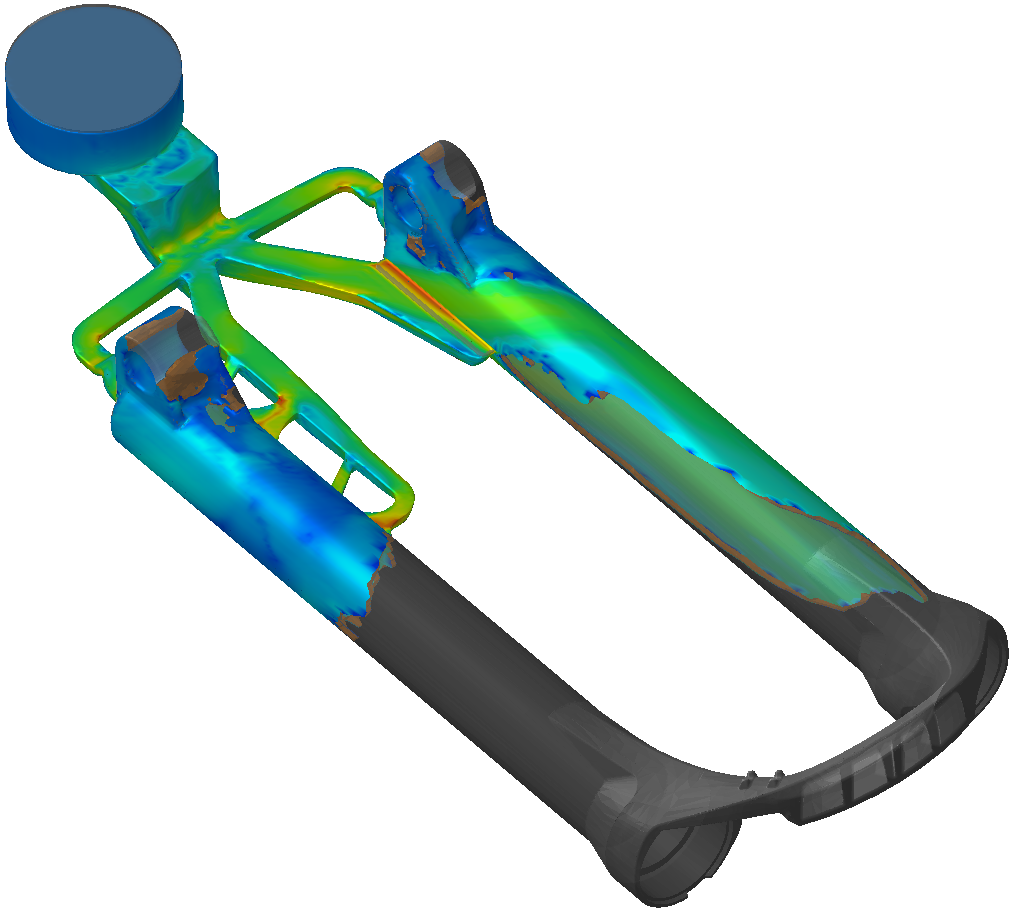

EKKcapcast is a powerful and flexible software, capable of simulating every casting process. Select a process from a sampling on the left for more information. Contact us if you don't see your process listed so we can give you more specific details.

High Pressure Die Casting

The entire casting process is simulated - everything from ladling to die spray. We can design complete runner systems, perform stress analyses on the mold and casting, or simply diagnose problematic flow patterns.

Low Pressure

EKKcapcast's two-phase flow solver is able to use pressure to dictate filling conditions in a variety of configurations making modeling LP, PCPC/ACPC, and VRC/PRC all possible. Real time effects of cooling line configurations can be observed.

SPM & Tilt

Semi-Permanent Mold castings are often quite large and complex making for very demanding simulation work. EKKcapcast is up to the challenge thanks to the advantages offered by our specially designed FEM mesh generator. With moving model capabilities, Tilt pour flow can be easily and accurately modeled.

Printed Sand &

Sand Casting

The solidification module was the first EKK Inc. developed over 25 years ago. Advances since have only led to reduced simulation time and improved accuracy. Real time effects of chills on solidification patterns can be observed.

Other Processes

EKKcapcast simulation software can be used for modeling other casting processes in addition to HPDC, LP, SPM, and Sand castings. Our mesh generator can be applied to any casting process.

Consulting Services

The engineers at EKK have over 15 years of experience applying EKKcapcast metal casting simulation software to a wide variety of casting concerns. The consulting side of the business is housed under the same roof as the software development side, so each team can work together to most efficiently solve your casting problems. This environment provides for collaboration that enables

HPDC gating design services provided by EKK Inc. will save your company time and money all while resulting in a better final casting. We will work closely with you to design a complete gating and overflow system for your casting. Our tried-and-true approach towards gating design overcomes the limitations of traditional gating design techniques to help you be as competitive as possible in today’s global market.

By taking advantage of the advanced casting simulation technologies present in EKKcapcast, the experienced engineers at EKK Inc. can help you develop and optimize your casting process. We take our time to communicate with you and fully understand your process and goals. No matter what you want accomplished, we can probably help you.

Improve Your Business

Reduce Costs

Improved yields as well as less physical mold alterations and tests results in decreased development time and part costs.

Spend Less Time

Decrease development lead times by quickly iterating your design in the virtual world. Find the best casting before you cut the mold.

Improve Yield

Optimal efficiency and design means better parts with less waste. No more over engineered gating and risers.

Know More

The amount of data collected using EKKcapcast means you'll know more about your casting process than you ever have before.

Find issues

You will be able to find casting problems and inefficiencies before you even cut the mold.

better castings

Get the best casting the first time – every time.

Contact Us

29551 Greenfield Rd Ste 209, Southfield, MI 48076

Phone: (248) 624 - 9957

Email: info@ekkinc.com

See what we can do for you