Powerful

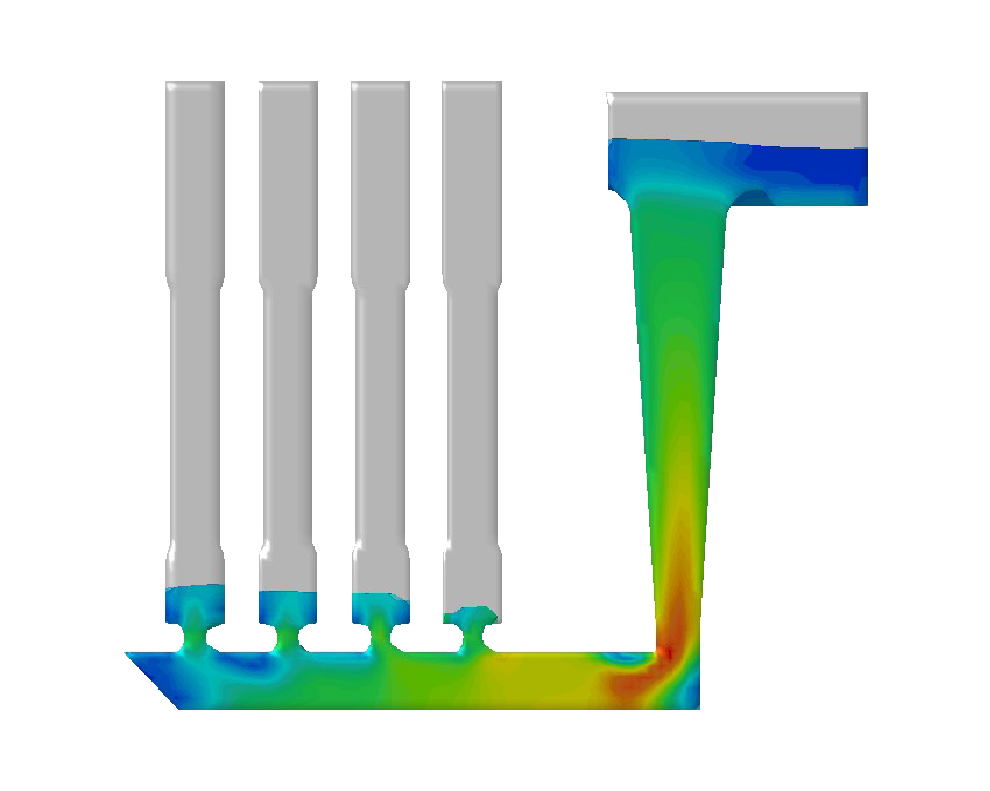

EKKcapcast calculates a wide range of data using advanced techniques and powerful solvers. A complete data set assures you have everything you need to get your casting right the first time.

• Fill Time Prediction

• Cold Shuts

• Riser Sizing & Placement

• Pipe Prediction

• Porosity Prediction

Natural Solidification

The Natural Solidification process in EKKcapcast is faster and easier than ever. The simplicity of Natural Solidifications enable them to augment your entire casting operation at every stage: design risers, gating, and chill configurations, identify defects, or simply help visualize the otherwise abstract process of solidification.

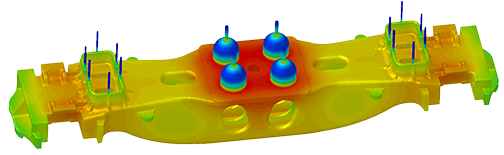

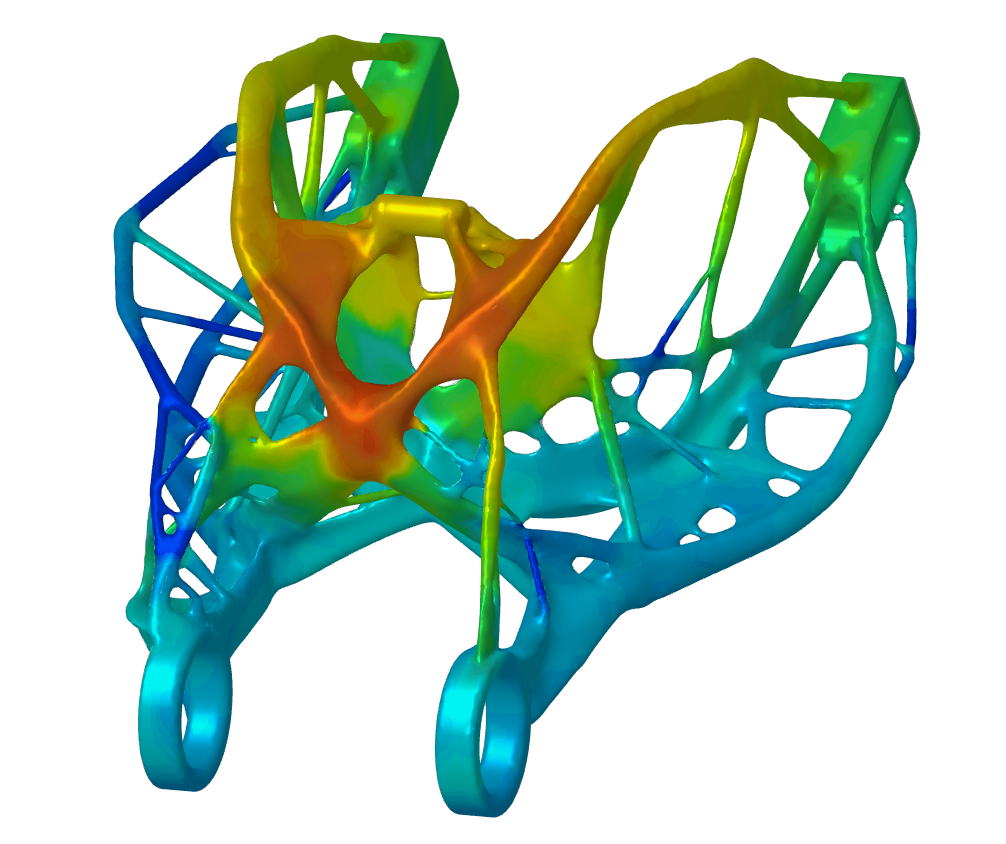

Perfect for 3D Printed Sand

3D Printed Sand provides design opportunities that no other metal forming process can offer. With it's ability to accurately model the casting geometry, EKKcapcast's FEM mesh is the perfect fit for 3D Printed Sand casting process simulation of highly complex organic geometries derived through topology optimization or generative design technologies.

FDM Mesh

FEM Mesh

Accuracy

The high quality FEM meshes produced by EKKcapcast, coupled with its powerful simulation solvers, result in unprecedented levels of accuracy. Filters —commonly included in gravity castings— in addition to regulating metal quality can dramatically impact flow patterns and thereby trapped air. Simulation results are consistently verified by real world castings.

No Filter

20mm 30 PPI Filter

J. Bäckman et.al., “Influence of filter on the mould filling of aluminium melts in vacuum-sealed moulds”, Jönköping University, Sweden, 1999

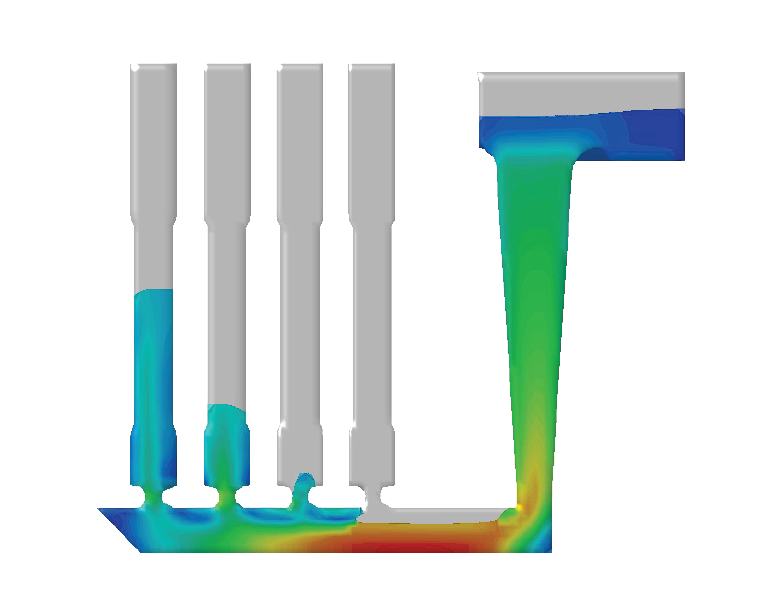

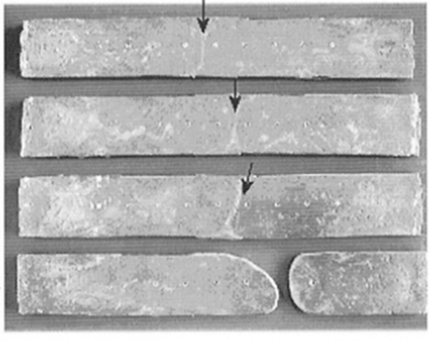

Mis-Runs

Properties such as the changing viscosity of an alloy as it cools can be modeled, thereby directly and visually predicting mis-runs. Simulation results are consistently verified by real world castings.

| Temperature °C | |

|---|---|

| Left Gate | Right Gate |

| 750 | 700 |

| 750 | 670 |

| 750 | 650 |

| 750 | 630 |

S.Kashiwaki et.al., J. JFS, Vol. 78, No. 5 (2006), pp.245~251

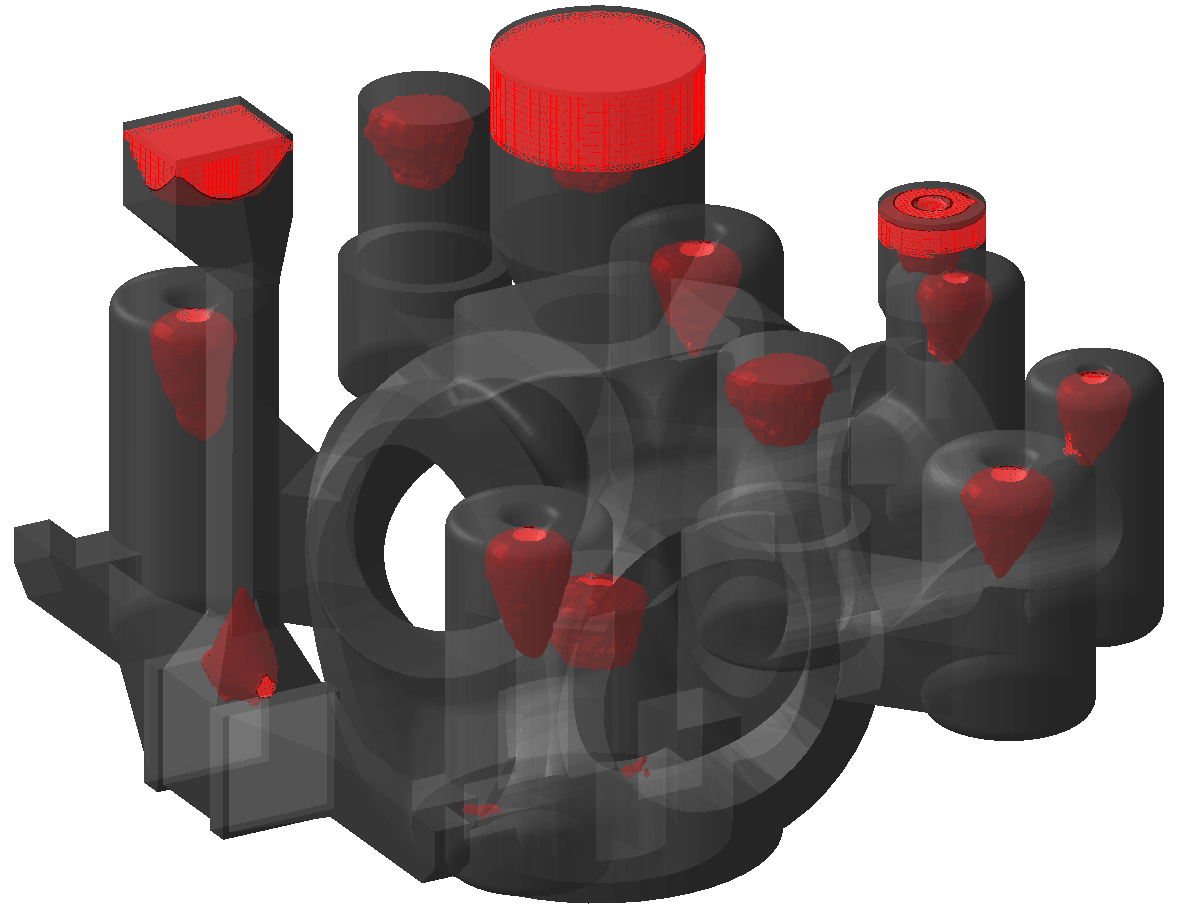

Solidification & Porosity

Thermal results are used to predict hot-spot locations and sites of potential defects. Optimal chill placement can be quickly determined using hot-spot data to improve feed paths. The porosity module uses material property data to greatly improve the quality of predictions. Porosity defects, temperature gradients, and cooling rates are taken into account by the software to accurately determine mechanical properties. The effect of inoculation can also be observed in the porosity results.

Heat Transfer

EKKcapcast’s thermal analysis module uses zero-thickness interface elements to connect components and accurately model heat transfer between them. Temperature dependent material properties, thermal expansion, and changing water content in green sand are all modeled. The ability to analyze casting temperatures, solidification patterns, and thermal effects throughout the entire process is an indispensable tool.