Reduce / prevent scraps

Reduce cycle times

Increase tool life

Educate process engineers

What We Do

By taking advantage of the advanced casting simulation technologies present in EKKcapcast, the experienced engineers at EKK Inc. can help you develop and optimize your casting process. We take our time to communicate with you and fully understand your process and goals. No matter what you want accomplished, we can probably help you.

Get In TouchWhat We Can Provide

-

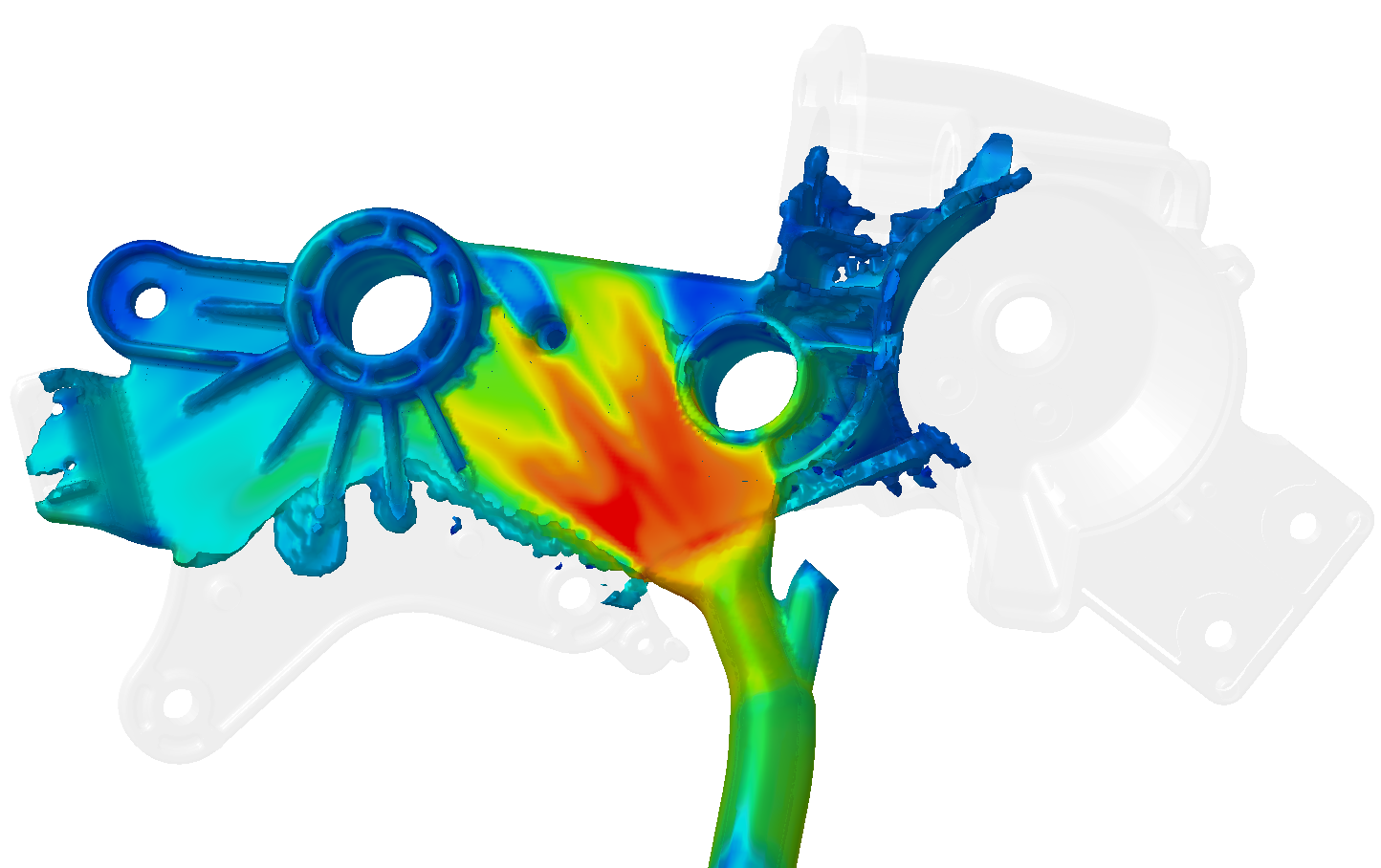

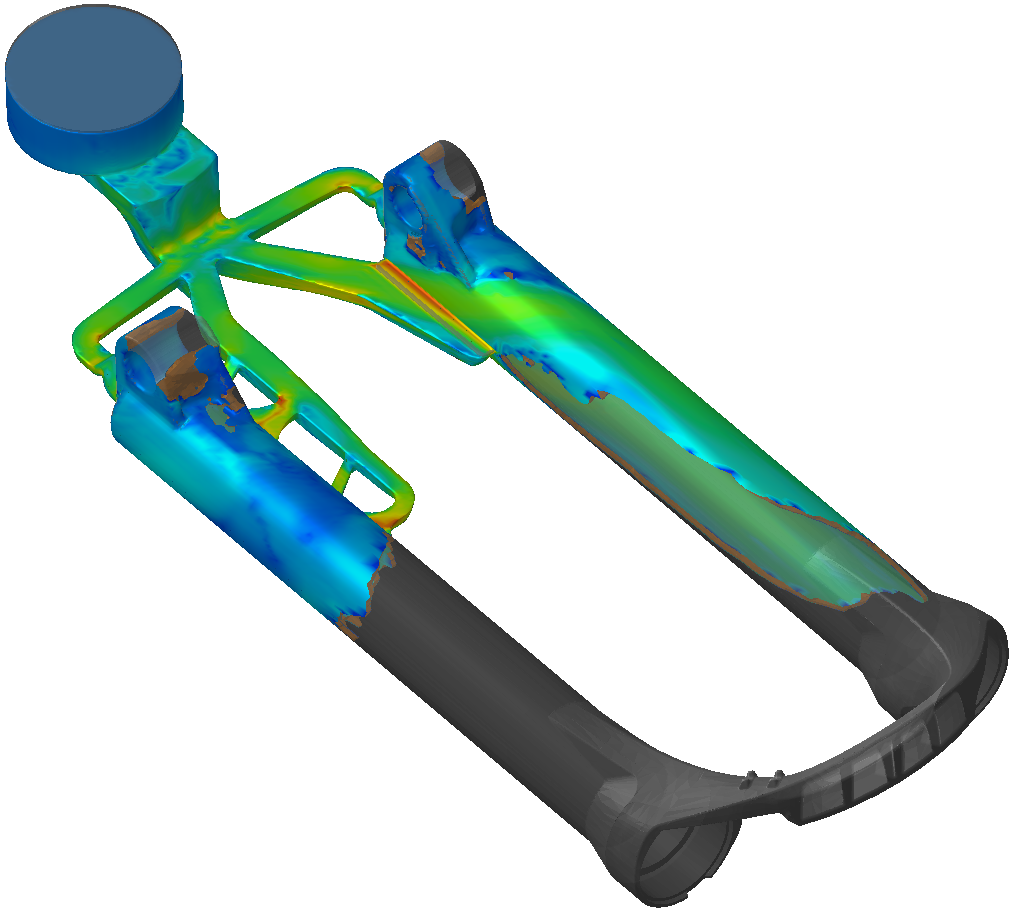

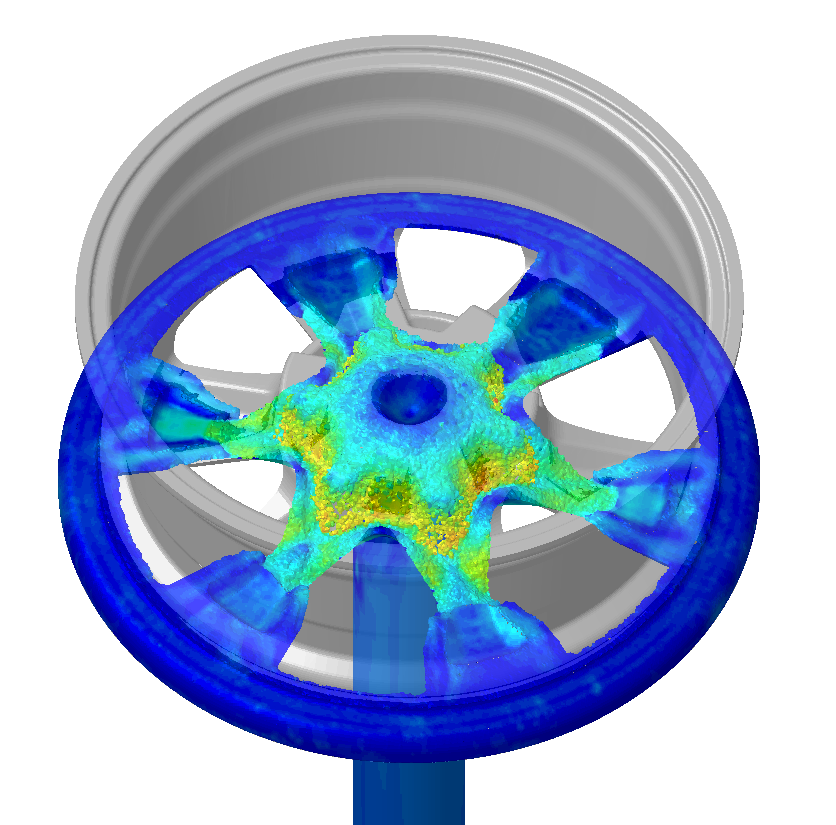

Thermal / Solidification Analysis

-

• Temperature plots of the casting / mold

• Solidification animation (AVI / GIF)

• Solidification time verification

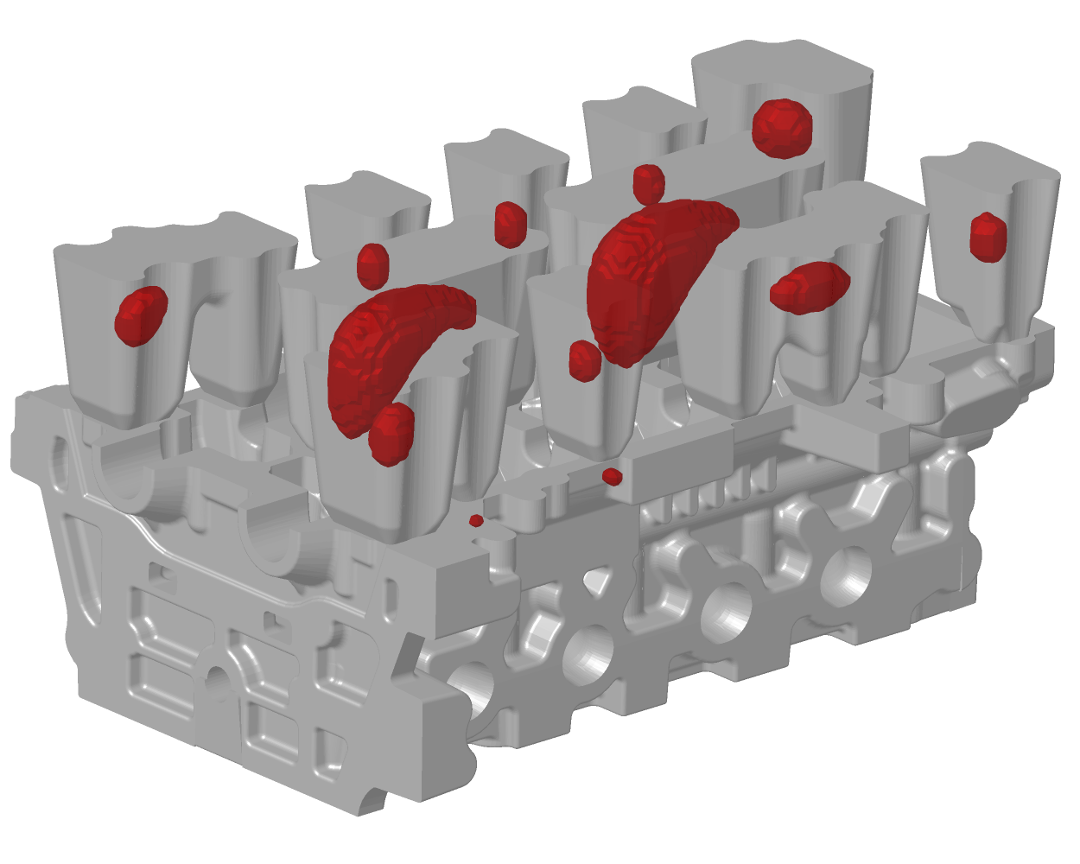

• Shrinkage (hot spots)

• Recommendations on gating / riser / chills / cooling locations -

Flow Analysis

-

• Filling pattern animations (AVI / GIF)

• Fluid front

• Velocities

• Temperature

• Trapped gas / oxide defects

• Particle tracking

• Air / Back Pressure

• Filling rate / Time Verification

• Predict cold shuts / mis-runs

• Recommendations on fill pressure / fill rate / overflows / venting / temperature

-

Porosity Prediction Analysis

-

• Micro-structure

• Analyze mechanical properties of the casting for reference

-

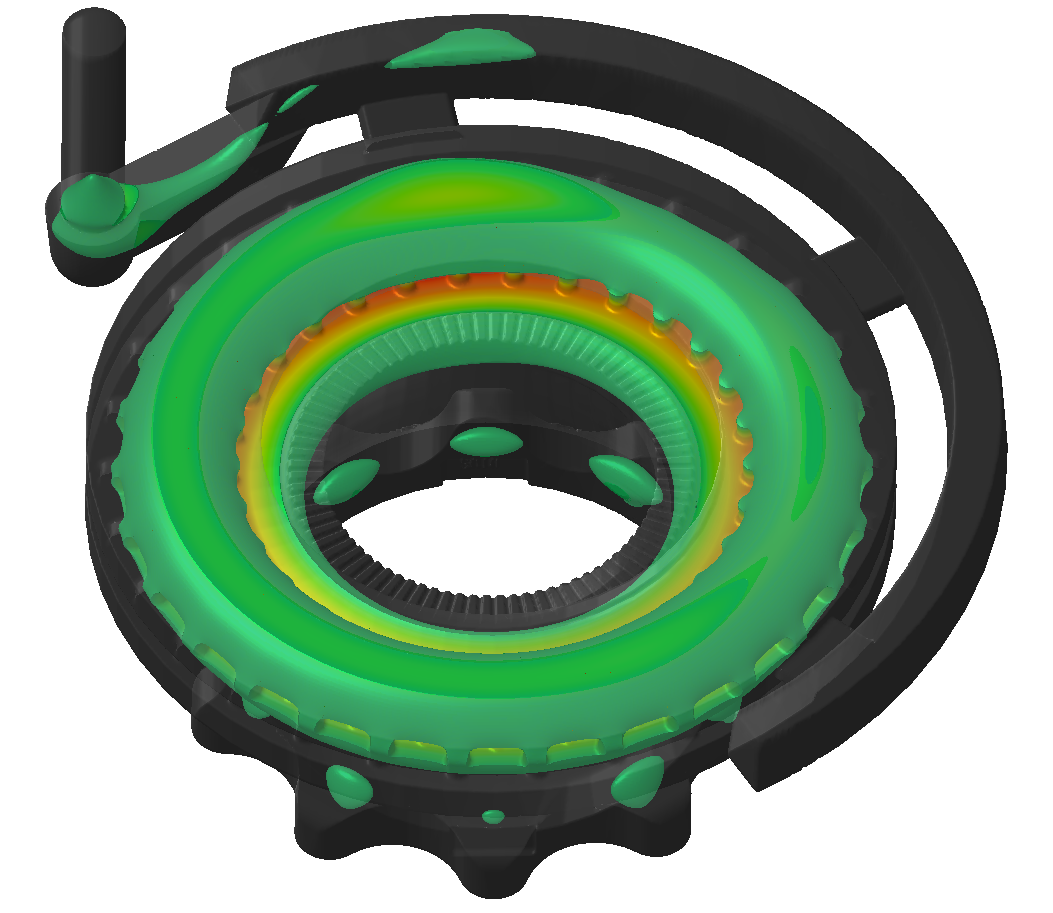

Stress / Distortion Analysis

-

• Deflection / distortion of the casting after ejection

• Identify interference / gap problems on molds

• Analyze thermal fatigue of molds

What It Means For You

Reduce Costs

Improved yields as well as less physical mold alterations and tests results in decreased development time and part costs.

Spend Less Time

Decrease development lead times by quickly iterating your design in the virtual world. Find the best casting before you cut the mold.

Improve Yield

Optimal efficiency and design means better parts with less waste. No more over engineered gating and risers.

Know More

The amount of data collected using EKKcapcast means you'll know more about your casting process than you ever have before.

Find issues

You will be able to find casting problems and inefficiencies before you even cut the mold.

better castings

Get the best casting the first time – every time.

Processes

The engineers at EKK, Inc have years of experience working in the casting industry. Our expertise and familiarity with both casting itself and using the software guarantees the best results.

EKKcapcast is a powerful and flexible software, capable of simulating every casting process. Select a process from a sampling on the left for more information. Contact us if you don't see your process listed so we can give you more specific details.

High Pressure Die Casting

The entire casting process is simulated - everything from ladling to die spray. We can design complete runner systems, perform stress analyses on the mold and casting, or simply diagnose problematic flow patterns.

Low Pressure

EKKcapcast's two-phase flow solver is able to use pressure to dictate filling conditions in a variety of configurations making modeling LP, PCPC/ACPC, and VRC/PRC all possible. Real time effects of cooling line configurations can be observed.

SPM & Tilt

Semi-Permanent Mold castings are often quite large and complex making for very demanding simulation work. EKKcapcast is up to the challenge thanks to the advantages offered by our specially designed FEM mesh generator. With moving model capabilities, Tilt pour flow can be easily and accurately modeled.

Printed Sand &

Sand Casting

The solidification module was the first EKK Inc. developed over 25 years ago. Advances since have only led to reduced simulation time and improved accuracy. Real time effects of chills on solidification patterns can be observed.

Other Processes

EKKcapcast simulation software can be used for modeling other casting processes in addition to HPDC, LP, SPM, and Sand castings. Our mesh generator can be applied to any casting process.